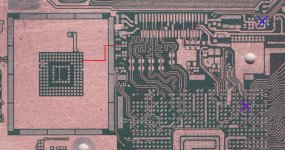

https://gbatemp.net/threads/picofly-a-hwfly-switch-modchip.622701/post-10171602So I did some research. These resistors on an OLED CMD should show 4.7k and 47 ohms right? Mine showed no value when tested and in diode they show 350 one way, 750 the other. This means they've blown? (I have a black screen when booting).

If so what size are the resistors so I can order new ones and can a faulty CPU flex cable install cause them to blow? I still need to work out what happened.

4.7K and 47K

" Mine showed no value when tested"

If what you mean is

you test the resistance value and it is not measured,

than surely its damaged, need to replace.

Last edited by abal1000x,

I initially thought I maybe overheated them during the soldering but I only tapped with the iron, not held it there. So I'm wondering what could cause them to blow...

I initially thought I maybe overheated them during the soldering but I only tapped with the iron, not held it there. So I'm wondering what could cause them to blow...