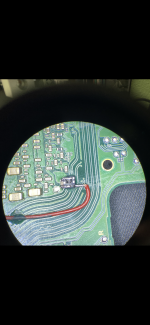

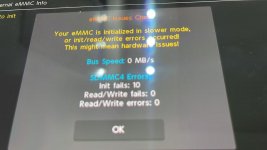

I finally got my hands on the Zelda Oled that I ordered 3 months ago and I decided to try and set a proper dat0 by removing the emmc.

A couple of things to point out:

- It was easier than I thought but I've been preparing/practicing this for quite some time so for anyone reading this I would suggest you do your homework before diving in.

- The amount of beating these chips can handle is quite impressive.

- Same as Takezo-San wrote a couple of post above, I had no luck with stencil and paste (maybe I was stressed and tired because I started doing this at 11pm) so after trying a couple of times and failed I just did it manually one by one with 0.3 balls.

Everything went smoothly afterwards and since the board was already off I also decided to try the abal's mosfet placement on the back of the apu.

I just want to say that this is an amazing thread with some amazing people and the list of people to say thank you is way too long but I have to point out @Dee87 and @Takezo-San without whom I probably would have not had the courage/will to go through with this process and a special thanks to @abal1000x who’s dedication and contribution to this whole mod is priceless.

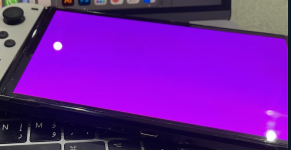

Below you can see some pictures, I should have done more but I got carried away in the heat of the moment

Nice looking good :-)

What was ur issue with the stencil?

U have to put magnet or something around the emmc so the rest of the stencil is laying on something so it doesn't have that much chance of bending.

Then add ur solder paste , if u have enough set ur tweezers in the middle of the stencil and push it on the emmc.

Then set ur hot air at 180 a bit more then ur pastes melting point and slowly best ur stencil up don't go straight to the stencil so its not a heat schock otherwise it Gonna bend really fast due to the heat.

Wait till everything is melted but always keep pressure on the middle of the stencil.

After that I usually add a bit flux heat it up one more time and then take the stencil off