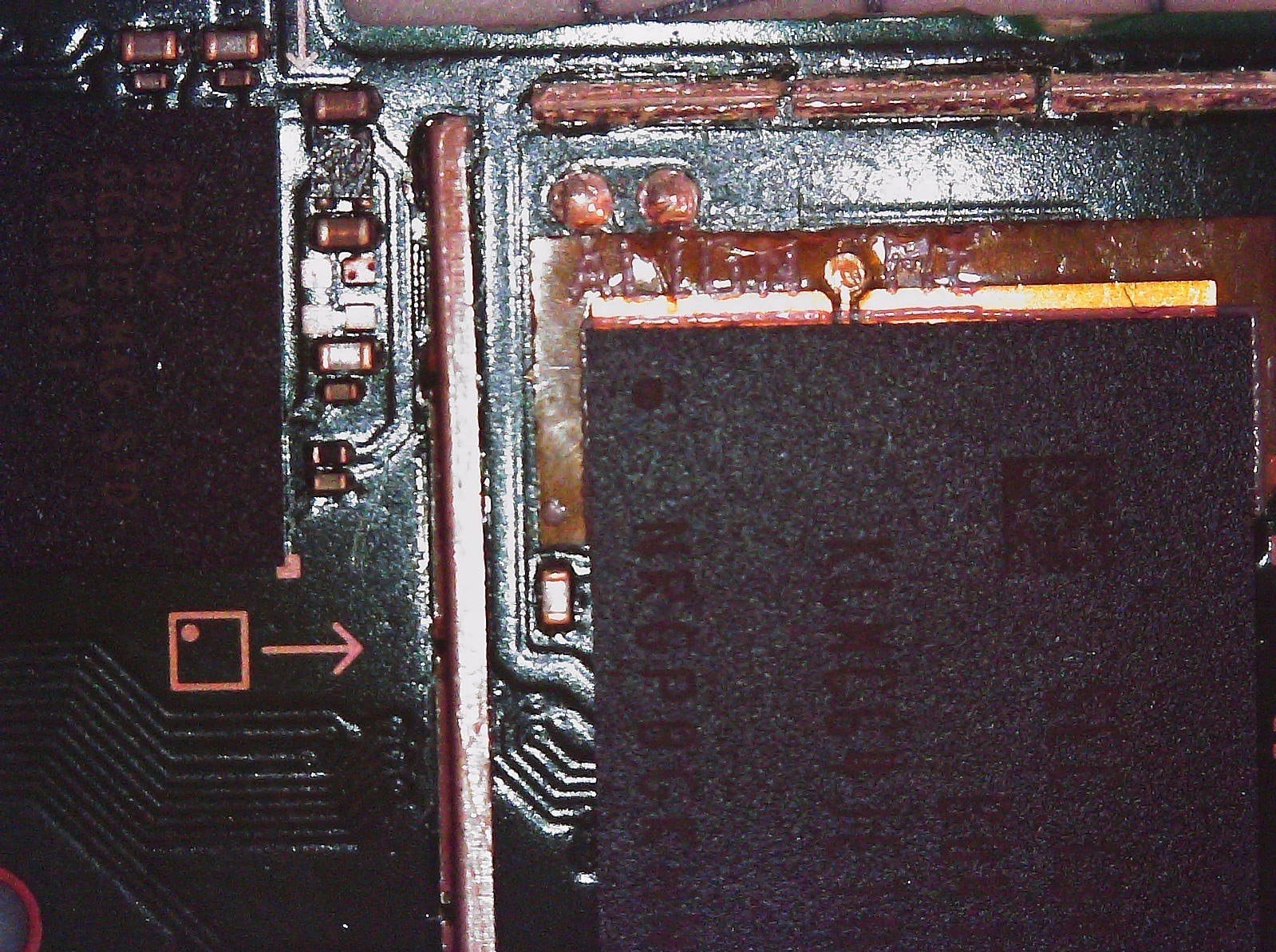

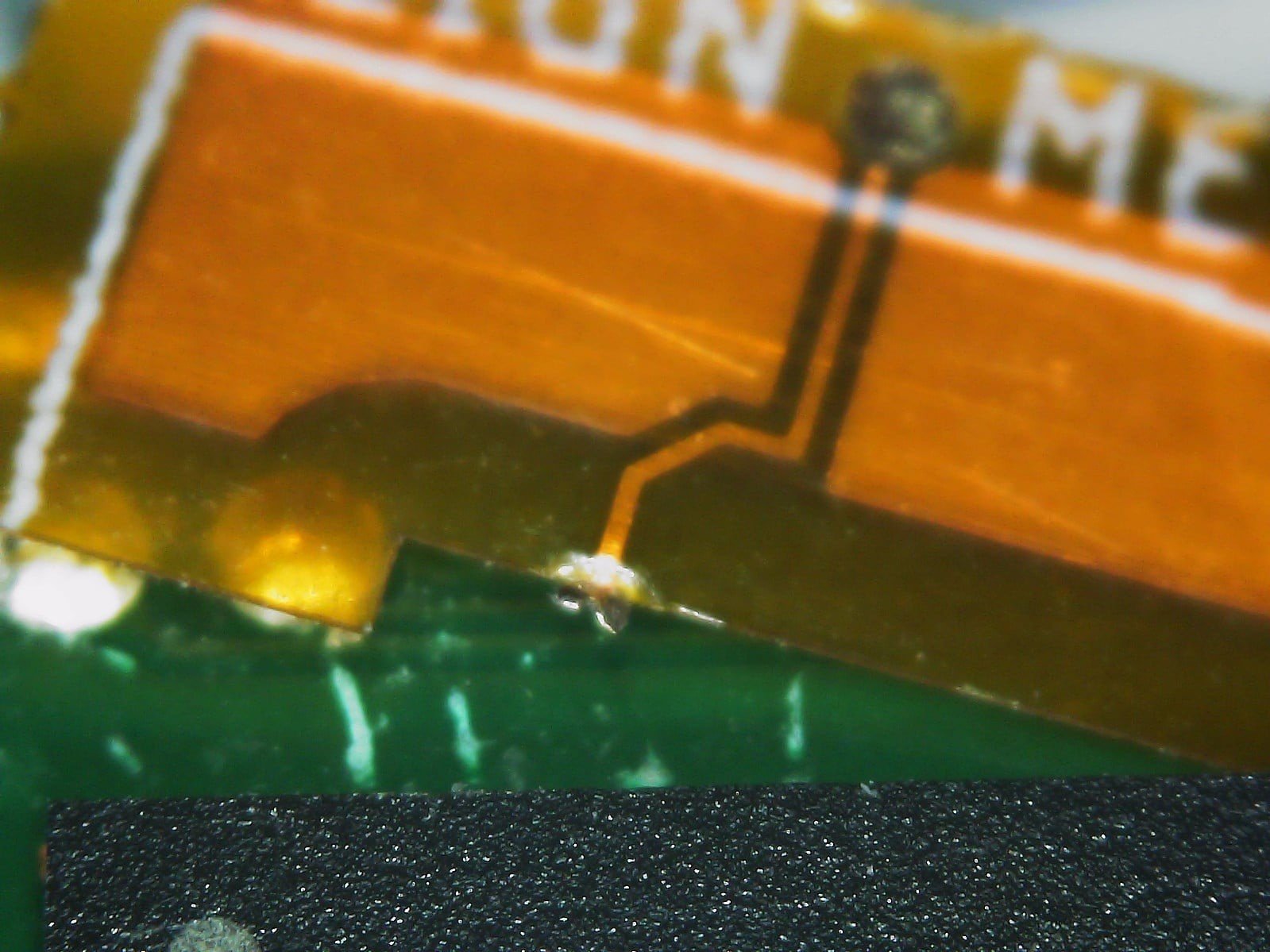

So after practicing micro soldering for a couple of weeks, my HWFLY chip finally showed up. However, I can't get a DAT0 connector to make continuity with ground. I tried with one of the original adapters, and one of the newer corner adapters. No matter how many times I moved them, I could never get the pad and ground point to make a connection.

Am I missing something? Both adapters have continuity within the adapter themselves. It looks simple on YouTube vids, but I can't figure it out.

I realize the one adapter is slightly bent in the pic. But I've flattened it out and maneuvered it around countless times. Still no dice.

Here are some pics:

Am I missing something? Both adapters have continuity within the adapter themselves. It looks simple on YouTube vids, but I can't figure it out.

I realize the one adapter is slightly bent in the pic. But I've flattened it out and maneuvered it around countless times. Still no dice.

Here are some pics: