Hello,

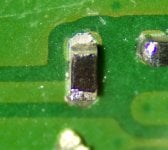

When working on modding an OLED Switch, I ended up lifting part of the pad my wire was attached to (I'm using 30 gauge wire as part of an INSTINCT V6 install). I've attached a photo of the top of the resistor I soldered for the A/CMD point. I think I was using too much heat and tugged on the wire before it was properly cooled.

The resistor (4.7k 0201) is still firmly attached to the Switch motherboard, and I haven't attempted to put the console back together yet to see if it will boot into the original firmware. I was wondering if there are any other points I could tap into for the A/CMD line. I can test by re-assembling the console as is (without soldering the other ends of the wire to the mod chip) and seeing if it boots fully, indicating the resistor is fine. But if there's no alternative point for the A/CMD line, I need to remove the 0201 4.7k resistor and attempt to repair the pad.

I hope to use Kapton tape to insulate the area around the damaged pad, then use hot air, lift the old resistor off (any suggestions on temperature for the hot air?) and then use what's left of the pad for the repair. I have some 3M Copper Shielding Tape 1125 and pad repair strips. I might use the pad repair strips over the tape, but either should work. I'd use some solder to bridge between the tape/pad and what's left of the original trace. I'd use UV solder mask to bond the repair to the PCB, and then I should be able to place a new 0201 4.7k resistor and the A/CMD wire and finish this install.

All the other points went well; I found the D/CLK point tricky. I scraped gently with an xacto and used a 30 gauge wire there. I could get solid adhesion with the solder, but it felt fragile. I had some PCB-safe RTV162 (used for supporting large capacitors) to give it some more support and a dab of superglue further downstream of the wire to reduce strain on the joint itself.

Any suggestions would be appreciated as well, as well as any way to use a multimeter to check my work concerning the other points (I've seen some posts about diode values)

Thanks!

When working on modding an OLED Switch, I ended up lifting part of the pad my wire was attached to (I'm using 30 gauge wire as part of an INSTINCT V6 install). I've attached a photo of the top of the resistor I soldered for the A/CMD point. I think I was using too much heat and tugged on the wire before it was properly cooled.

The resistor (4.7k 0201) is still firmly attached to the Switch motherboard, and I haven't attempted to put the console back together yet to see if it will boot into the original firmware. I was wondering if there are any other points I could tap into for the A/CMD line. I can test by re-assembling the console as is (without soldering the other ends of the wire to the mod chip) and seeing if it boots fully, indicating the resistor is fine. But if there's no alternative point for the A/CMD line, I need to remove the 0201 4.7k resistor and attempt to repair the pad.

I hope to use Kapton tape to insulate the area around the damaged pad, then use hot air, lift the old resistor off (any suggestions on temperature for the hot air?) and then use what's left of the pad for the repair. I have some 3M Copper Shielding Tape 1125 and pad repair strips. I might use the pad repair strips over the tape, but either should work. I'd use some solder to bridge between the tape/pad and what's left of the original trace. I'd use UV solder mask to bond the repair to the PCB, and then I should be able to place a new 0201 4.7k resistor and the A/CMD wire and finish this install.

All the other points went well; I found the D/CLK point tricky. I scraped gently with an xacto and used a 30 gauge wire there. I could get solid adhesion with the solder, but it felt fragile. I had some PCB-safe RTV162 (used for supporting large capacitors) to give it some more support and a dab of superglue further downstream of the wire to reduce strain on the joint itself.

Any suggestions would be appreciated as well, as well as any way to use a multimeter to check my work concerning the other points (I've seen some posts about diode values)

Thanks!

Attachments

Last edited by OctuplePrecision,