I've been trying to fix this blasted Xbox 360 Slim for ages now and finally came across a fix that involves replacing resistors R4D3, R4D4, R4D5, R4D6, R4D7 and R4D8. I saw a recommendation to bridge the connections instead if you don't have correct replacement resistors (I currently don't but would like to get them for future-proofing).

Anyway, R4D7 was bad but I decided to replace them all because it was "easier" (it's hell either way, especially with a shitty soldering iron not designed for SMD soldering).

So after repairing it successfully (I honestly was not expecting such a result), I decided to clean up some of the flux... because apparently leaving it alone was too good to be true. I knocked off the joint on R4D7 and it ripped the solder points right off. Tried to scrape at the traces to fix it but no luck.

TL;DR does anyone know of alternate solder points for R4D7 (and all the others as well, just in case)? I don't mind using wires etc. - I just want to fix this damn thing after it failed for no reason (seriously, it was hardly used and hadn't been touched for a while when it died).

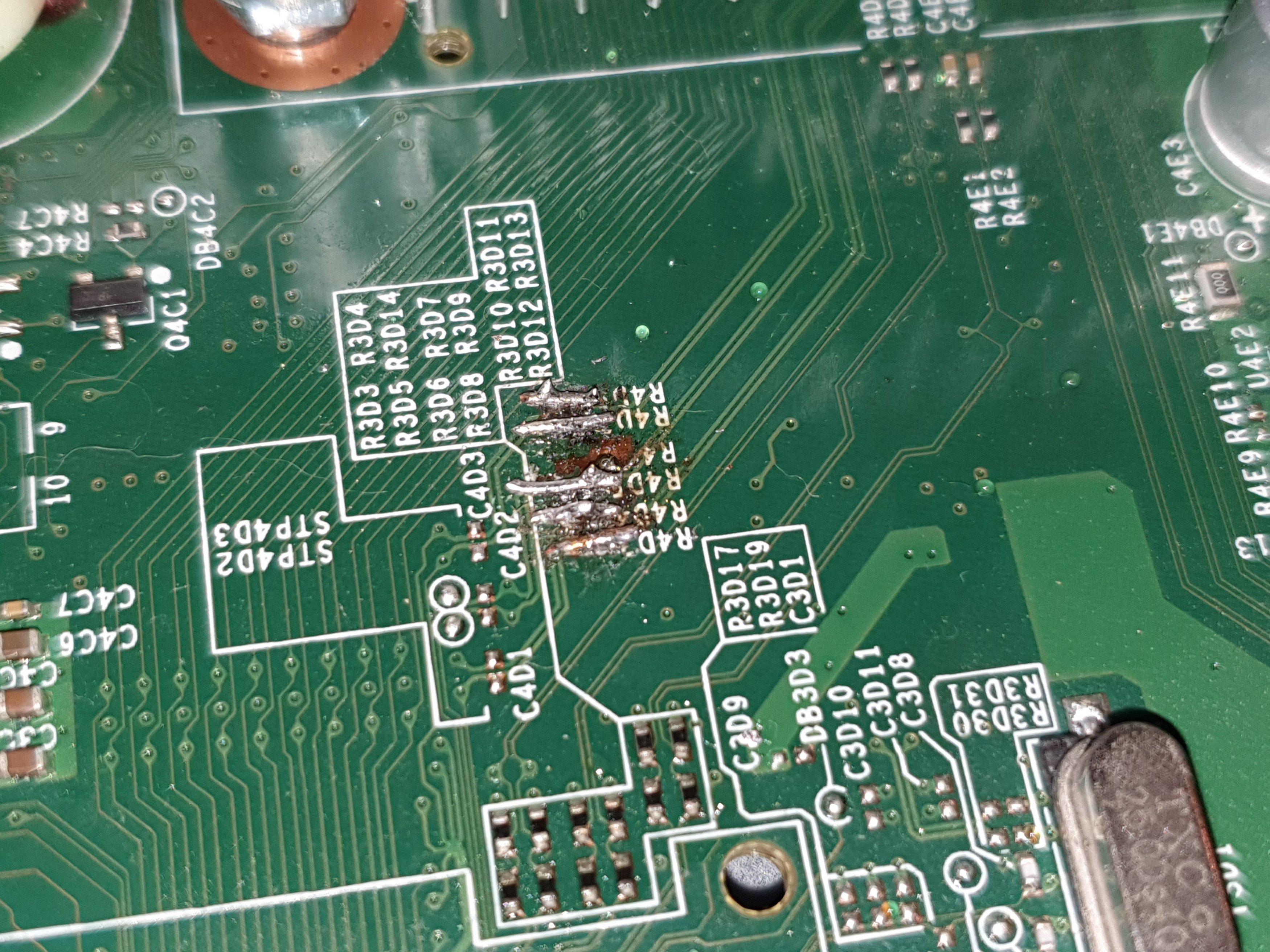

I've attached an image of my shitty hack-job in case it helps (yes it's horrendously bad - you try doing SMD soldering without the right tools and tell me how well it goes).

Anyway, R4D7 was bad but I decided to replace them all because it was "easier" (it's hell either way, especially with a shitty soldering iron not designed for SMD soldering).

So after repairing it successfully (I honestly was not expecting such a result), I decided to clean up some of the flux... because apparently leaving it alone was too good to be true. I knocked off the joint on R4D7 and it ripped the solder points right off. Tried to scrape at the traces to fix it but no luck.

TL;DR does anyone know of alternate solder points for R4D7 (and all the others as well, just in case)? I don't mind using wires etc. - I just want to fix this damn thing after it failed for no reason (seriously, it was hardly used and hadn't been touched for a while when it died).

I've attached an image of my shitty hack-job in case it helps (yes it's horrendously bad - you try doing SMD soldering without the right tools and tell me how well it goes).

JM

JM