Possible? Plenty of people have done things like it.

In this case. Your main trouble will be the type of switch used.

Broadly speaking there are two types of momentary switch (as opposed to latching switch that needs another press/release to change, think most household light switches), that being

Push to Make aka PTM

Push to Break aka PTB

PTM makes a circuit, e.g. in your basic battery, lightbulb, switch, wires affair the switch gets pressed and while it is held the light turns on as current is allowed to flow.

PTB breaks a circuit, e.g. in said typical circuit the lightbulb will be on until such a time as the switch is pressed, a which point there is a break in the wires made by the switch and the light turns off.

The vast majority of the time such things will be PTM switches but there are occasions otherwise. You could buy the other type (finding ones that fit perfectly might be tricky, however you presumable are comfortable working with physical things so could overcome that if necessary), and there are circuits that you could do to bypass but let's skip that for now.

Wiring it in then becomes a matter of finding which pins are what -- get your multimeter and set it to continuity mode (will have buzzer to indicate), hold it on different pins, press the button (helps to have a third hand) and hopefully the beeping changes. If your multimeter does not have a continuity mode then while I would suggest getting a better one then resistance mode will do (resistance should fall from basically infinite to basically nothing for PTM). If you don't have a multimeter then oh dear but still can get it done -- get said battery, lightbulb (or I guess LED and resistor of suitable value) and some wire and figure it out by when the light turns on or off and its relationship to the pressing of the button. Can be annoying to keep contact on the pins -- generally, solder mask, flux and possibly now decades of corrosion from being said in some wet basement do make it annoying but scrape it a bit or get a pin to press into it a bit to get below all that.

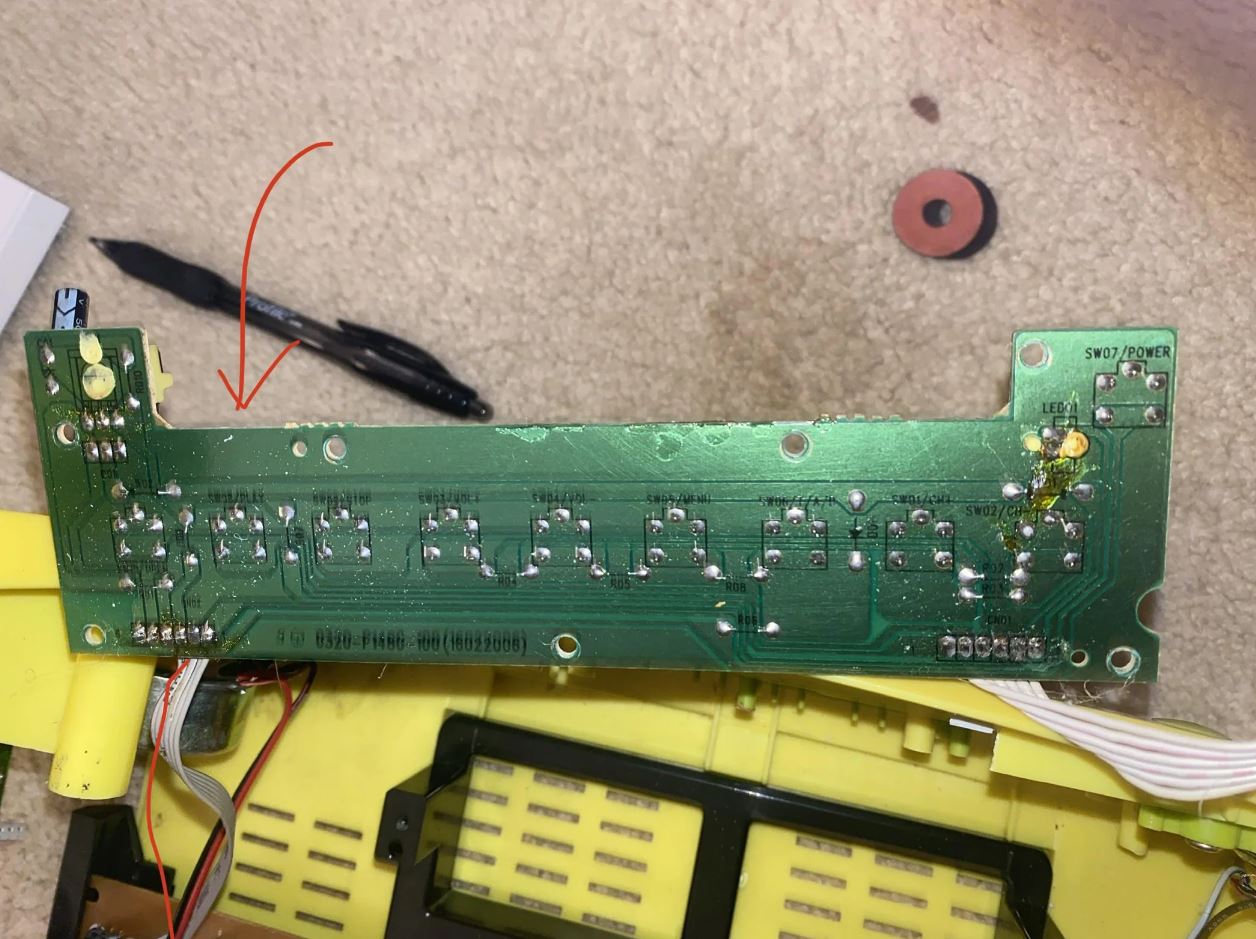

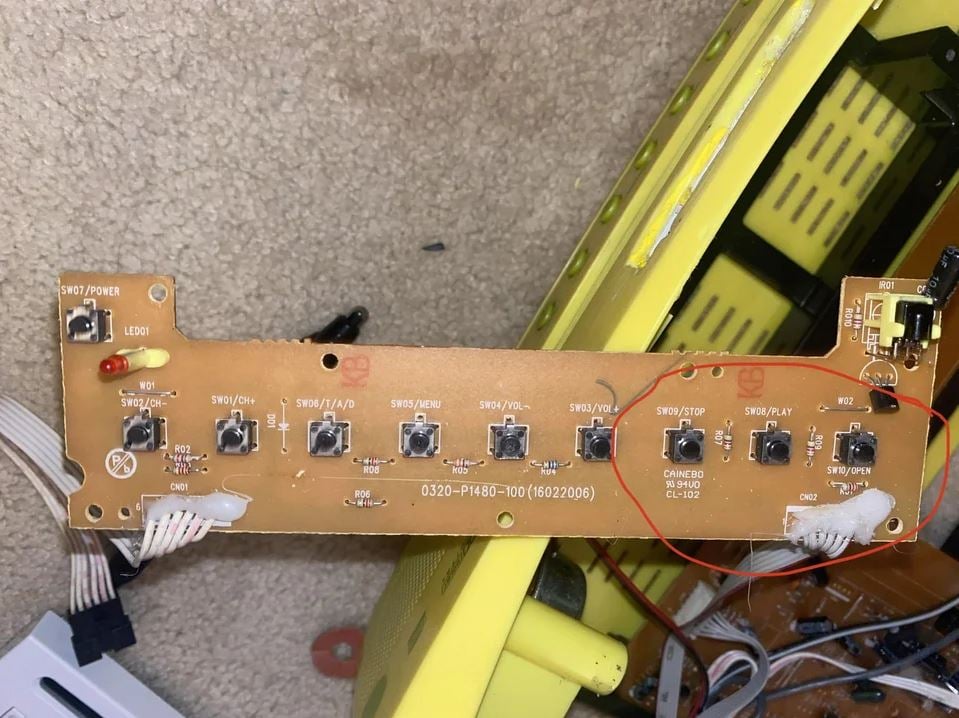

Where it gets marginally more tricky is ideally you want the switches totally isolated from the TV. I don't know what is on that board (I can see a LED and a capacitor on the other side which could interfere with things, as well as a whole bunch of resistors between the switches) or connected back into the TV and frankly you don't care to try to find out when you can cut the traces leading to the switch (probably on the other side of that board) such that the board is basically a gloried holder for the switch. You can do this with basic tools -- knife, rotary tool...

Fancier people might figure out if there is a shared ground*, or save themselves a solder job and solder into those white wires (cutting the TV aspect out of it), and if you are really good if the TV displays a probably nice green or grey icon for eject it might have that as well. Ignore them and just solder the 4 wires to the switches themselves or traces if that is easier (naturally do it on the side that the switch sees because you cut the traces like I told you to) because there is a test point (soldering onto switch pads is not as bad as legs of a modern chip but still annoying compared to a nice gold pad the factory used as a test point) or something.

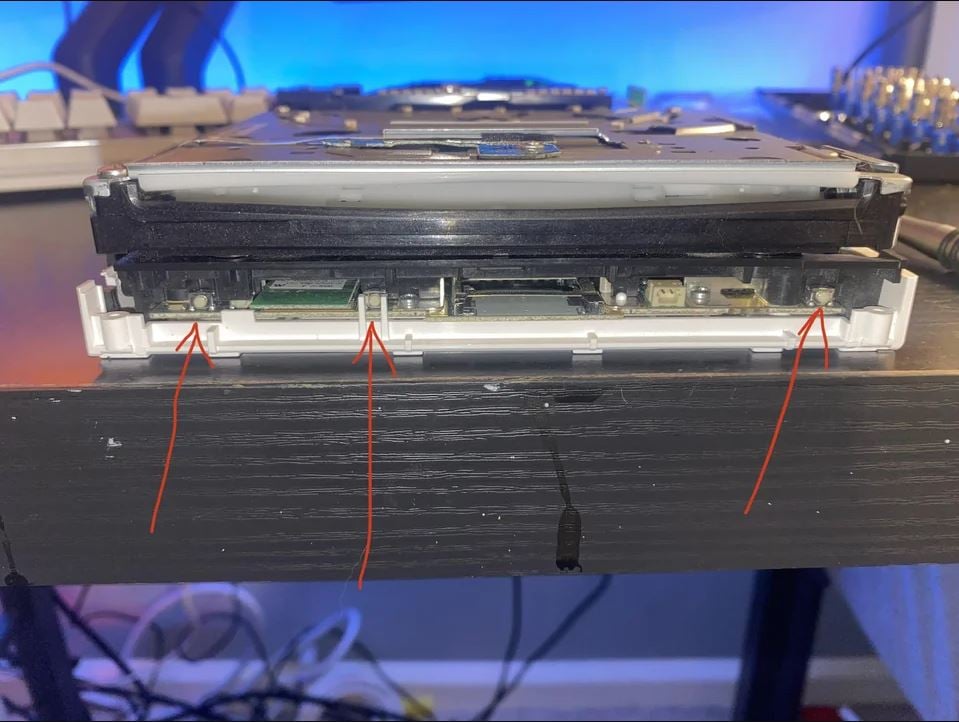

You will want to do the same on the Wii side of things and figure out its switch type, and what its equivalent pins are before throwing wires to the TV board. Some might have already done this for handheld wii adaptations as that is a fairly popular thing to do.

*most signals from buttons do something call pull up, or something called pull down. Pull up means there is say a 5V signal rail and the switch directs some of that into a pin such that it sees it and does something. Pull down means there is a ground (think 0V) that the switch provides a path to for the pin, which it sees and does something accordingly. Most things on a chip will be made to respond to the same thing so all the switches get access to the same thing and then get sent to their respective pins on the chip. Very nice if you have 10 switches to deal with but for two switches you need 3 wires rather than 4 so not much saved by doing it. The reason for isolating it is while I noted 5V as a signal above if the TV is some piece of late 80s tech it could be doing 12V or even 15V and the wii might not even be 5V as much as 3.3V so slamming 12V into that might make for a bad day.

That said three switches, or even 4 if you want to include the sync button for wiimotes as well, might seeing if there is a common rail/voltage used for this a more enticing prospect.