I'm having issues with my freshly modded Switch OLED.

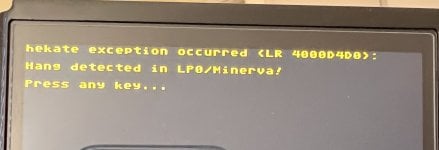

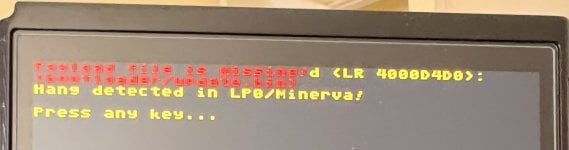

It was working and booting fine as soon as I installed the modchip but it was late so I shut it down and put it on charger for the night. The next day I went to install a larger SD card and got an error message. I've tried the old card but that didn't help. I've tried several other known good cards with no success. I've opened an issue in the hekate github repo and got a response that it's either fake or corrupted SD card or the SD connector itself (Update: contacted CTCaer directly and we came to conclusion that the issue is with one of the RAM modules). I don't think it's either one of those since I've been using tested good cards and opened the Switch and carefully inspected the SD connector and found no issues, all the pins look fine, nothing is bent or damaged.

Since I couldn't make the modchip work I decided to disconnect it. I desoldered and isolated all the wires from the chip and tried to boot the console. Got a blue screen. Tried to boot it holding the VOL+ and VOL- buttons but still getting the blue screen.

I'm not sure if simply desoldering the wires from the chip is enough to properly unmod the Switch but I couldn't find any proper instructions online.

Is there a way to make my Switch work again?

It was working and booting fine as soon as I installed the modchip but it was late so I shut it down and put it on charger for the night. The next day I went to install a larger SD card and got an error message. I've tried the old card but that didn't help. I've tried several other known good cards with no success. I've opened an issue in the hekate github repo and got a response that it's either fake or corrupted SD card or the SD connector itself (Update: contacted CTCaer directly and we came to conclusion that the issue is with one of the RAM modules). I don't think it's either one of those since I've been using tested good cards and opened the Switch and carefully inspected the SD connector and found no issues, all the pins look fine, nothing is bent or damaged.

Since I couldn't make the modchip work I decided to disconnect it. I desoldered and isolated all the wires from the chip and tried to boot the console. Got a blue screen. Tried to boot it holding the VOL+ and VOL- buttons but still getting the blue screen.

I'm not sure if simply desoldering the wires from the chip is enough to properly unmod the Switch but I couldn't find any proper instructions online.

Is there a way to make my Switch work again?

Attachments

Last edited by RubyRoid,