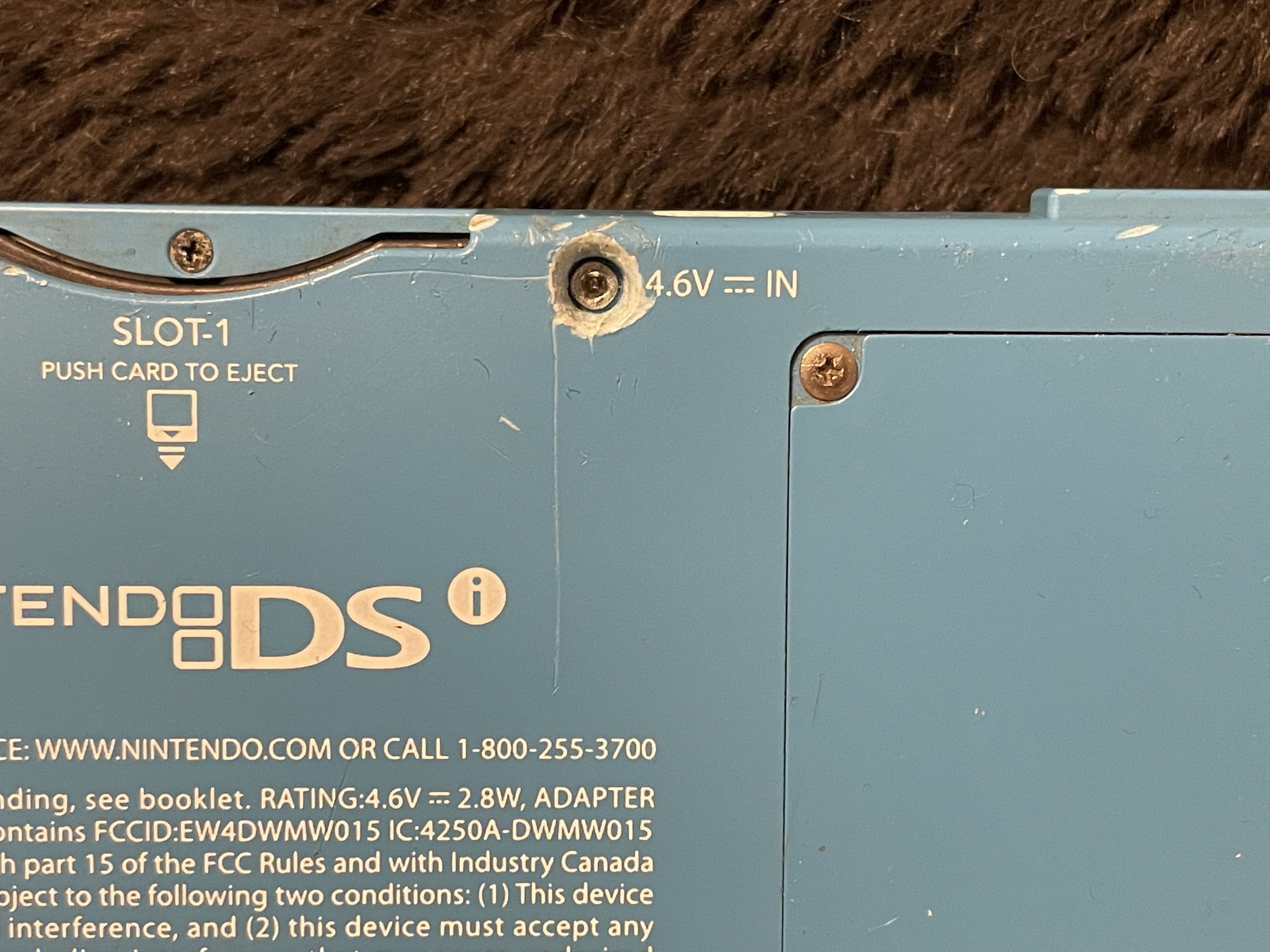

I just stripped a triwing screw in my brand new GBA shell (using the cheap triwing driver that came with it)

There's only a smooth round hole left, so rubber band, glue ext won't grib anything

How do you extract it after you drill?

Depending upon the setup it will just slide off and leave a threaded rod at this point sticking out you can grip onto with pliers, or maybe something a bit more locking (see vice/vise grips, though don't buy any specially) and twist out.

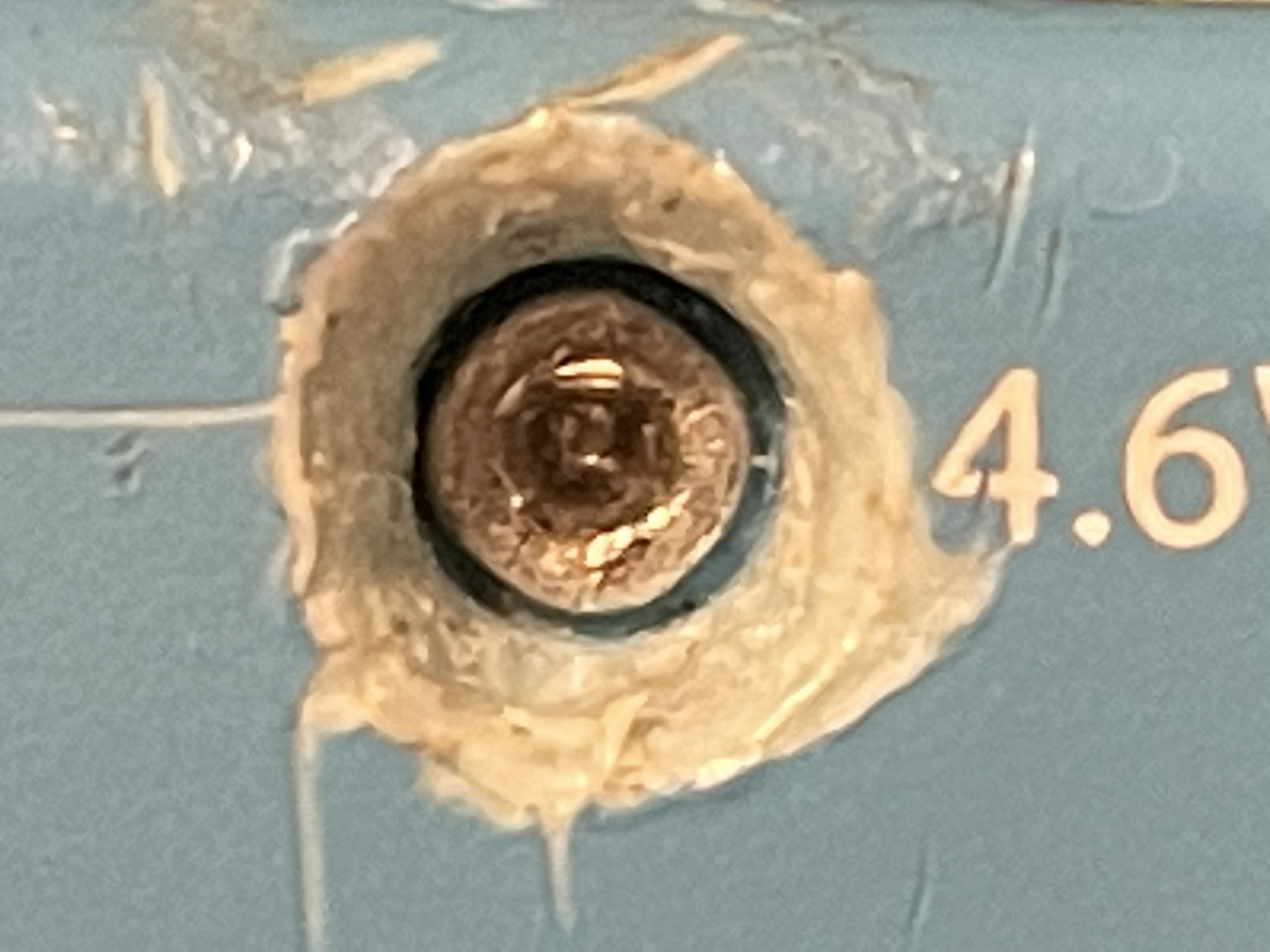

The general idea of drilling for most things like this is so the screw now has a nice hollow cone for a head and you can't or won't mill a new slot or have anything gain any purchase in what is there and thus the drilling.

Most drills will have an angled trip and thus by drilling down just a bit of a way you will detach the remains of the head which is the only thing providing any force to clamp the shell in most plastic and metal screw inserts things* I have ever pulled apart.

*two thick metal plates might be both tapped holes but this is not that.

Diagram, forgive the crudeness but hopefully it illustrates

The bit where it says not attached is indeed not attached if you did it right and should just fall out if you turn it upside down or hook it with a pick. Most will drill just a tiny bit into the remaining plastic to be sure or because they can't do better but you might find it breaks sooner than that or can be broken (if you can get a shim between the halves of the case then you can force upwards) when it gets really thin.

If "holding my hand steady and vertical is hard" then yes, yes it is. Why most that do it will want a drill press/drill stand of some form (borestander if my dictionary serves me here), mill or method that holds everything steady** for this sort of operation. Drill presses are for many the first step in any kind of machine tool setup and used by everybody from woodworkers on up and in many garages I go to.

If you are very good you can use an even smaller drill or milling bit to make a short line across the remaining head and thus turn it into a flat head screw, though that will likely be more specialist gear (I would probably go with carbide drill bits that they sell for drilling circuit boards***)

**you can hold a drill firmly on a bench, make sure everything is the right height and angle with some kind of holding jig and present the work to the drill. Tedious (especially if you have a bunch of different screws at different heights to do this for) but effective.

***circuit boards are made of various types of silicon carbide, which is basically a type of sandpaper/abrasive and will wreck metal drill bits in very short order hence these specialist drills that are quite cheap but will likely be specialist.