D

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Installed mine today in about an hour. Soldering took about 15 min using a cheap iron and $10 jewelers glasses. But I use to install original 30 wire xbox chips, so this was easy even with my now bad vision and shaking hands.

I thought I would share my progress so far with my preparation for this install.

I've been soldering for years but I've never done any SMD work, tiny or otherwise. It's something I've always wanted to do and I figured this would be a good time to learn a new skill and pick up some new kit.

The first thing I did was to pick up a practice SMD soldering board from ebay to see what kinda components I was dealing with. I got one of the 'blue' kits as they allowed you to practice with a decent range of package sizes down to 0402. I didn't know the switch capacitors were 0201 at the time, I'm going to look for a practice board with those on next. This is the blue practice board kit:

To get a scale of size, this is a MicroSD card and a grain of rice in comparison to the 0402 resistors...and bare in mind that the 0201 resistors are even smaller than that. I've posted Theorem's picture below for comparison again:

It was pretty obvious that I'm not going to be able to do this without some kind of magnification. I had previously tried using a 1x-14x head mounted magnifying visor in the past but I just couldn't get on with it. The main problem was the focal length. The greater the magnification, the smaller the focal length was. If I was using the higher end of the magnification the focal length was only a couple of inches which meant your head/lenses were right near the part and you risked stabbing yourself in the cheek with your iron I know people do use these and use them well but they're just not for me.

I know people do use these and use them well but they're just not for me.

After a lot of research looking into various types of magnification I decided that a stereo microscope was most likely going to give the best results. There are not too many choices for stereo microscopes. It seems to be either mid range hobby level or top end pro level. I opted for the former and bought a [Swift S42-20 Stereo Microscope].

I've got to say, equipment-wise this is one of the best things I've ever bought. It comes with 10x and 20x lenses, so far I've been doing everything with the 10x lenses which is more than adequate for 0402 and I imagine 0201 would be fine too, if not the 20x would certainly cover it. The two goose neck lights are great too but the best thing about this kind of magnification is the focal length! It's about 250mm/10" which is loads of room to swing your soldering around under and it's a much more comfortable height to be working at. The 'down side' to equipment at this price range is the fact that you do only have 10x and 20x fixed magnification. This is still fantastic though and I can't really see me needing any further magnification range or adjustment at this time. If you want to go down that route you're looking at something like the [Amscope SM-4B] that has adjustable 7x-45x magnification but it's also 2x the price. Maybe an upgrade for further down the line if required.....

Anyway, I digress. Using a microscope like this makes everything so much easier. I've never soldered any SMD stuff before and this made it a breeze, it almost feels like cheating

Initially, I had a TS-100 soldering iron with a stock TS-B2 tip and I only had some 1mm(0.040") solder as that's what I've generally been using for my cable assembly soldering. I did use these for a start to see how I got on and to be honest, I managed 'ok' with them. This is the stock TS-B2 tip and 1mm solder next to a 0402:

As you can see, the solder is pretty huge in comparison to the components and the iron tip isn't much better. I did manage to solder with these but it was hard to control the amount of solder and get nice concave joints. Even just tinning the stock tip put too much solder on for a 0402 component.

I picked up a TS-I tip for the TS-100 and I also bought some 0.38mm (0.015") and some 0.25mm (0.010") 63/37 leaded solder.

For comparison this is a TS-BC2 tip, the stock TS-B2 tip and the TS-I tip:

This is the 1mm solder, 0.38mm solder and 0.25mm solder:

There's not a massive difference between the 0.38mm and the 0.25mm solder in terms of usability. The 0.25 is a little more controllable but it does seem to be much harder to come by than the 0.38mm/0.4mm solder. If you can only get 0.38/0.4mm then that should be fine.

Just for comparison again, here's the 0402 resistors next to the TS-I tip and the 0.25mm solder:

I found the TS-I tip with it 0.2mm radius much easier to use and the finer solder made it much easier to apply an exact amount of solder. I know some people prefer the stock tip for micro soldering but I much prefer the finer one.

Side note: I picked up a [2UUL Universal Double Shaft High Temperature PCB Board Holder Fixture] which is ideal for this type of thing and should come in useful for lots of projects:

So my next step is to pick up some 0201 components and a test board. I'm pretty confident that I can do this install though after this bit of practice. If anyone is wanting to do this to their switch I would at least recommend picking up a practice board and trying out your soldering on that before attacking your switch. Most of the install videos I have seen so far have made me wince!

If I can give any other advice it would be:

Clean everything with IPA before starting.

Make sure you use flux, and use it often.

Watch your temps and solder time. You are better off using a higher heat for a short period of time than a lower temp for a longer period. Once again, practice.

Normally I pre-tin everything prior to bringing parts together and soldering but looking at the videos I have seen so far I think I'm going to get everything into position and then pre-tin the pads and then solder at the same time on this particular installation.

Hope that helps a little. I'm looking forward to the install once the chips are available!

I've been soldering for years but I've never done any SMD work, tiny or otherwise. It's something I've always wanted to do and I figured this would be a good time to learn a new skill and pick up some new kit.

The first thing I did was to pick up a practice SMD soldering board from ebay to see what kinda components I was dealing with. I got one of the 'blue' kits as they allowed you to practice with a decent range of package sizes down to 0402. I didn't know the switch capacitors were 0201 at the time, I'm going to look for a practice board with those on next. This is the blue practice board kit:

To get a scale of size, this is a MicroSD card and a grain of rice in comparison to the 0402 resistors...and bare in mind that the 0201 resistors are even smaller than that. I've posted Theorem's picture below for comparison again:

It was pretty obvious that I'm not going to be able to do this without some kind of magnification. I had previously tried using a 1x-14x head mounted magnifying visor in the past but I just couldn't get on with it. The main problem was the focal length. The greater the magnification, the smaller the focal length was. If I was using the higher end of the magnification the focal length was only a couple of inches which meant your head/lenses were right near the part and you risked stabbing yourself in the cheek with your iron

After a lot of research looking into various types of magnification I decided that a stereo microscope was most likely going to give the best results. There are not too many choices for stereo microscopes. It seems to be either mid range hobby level or top end pro level. I opted for the former and bought a [Swift S42-20 Stereo Microscope].

I've got to say, equipment-wise this is one of the best things I've ever bought. It comes with 10x and 20x lenses, so far I've been doing everything with the 10x lenses which is more than adequate for 0402 and I imagine 0201 would be fine too, if not the 20x would certainly cover it. The two goose neck lights are great too but the best thing about this kind of magnification is the focal length! It's about 250mm/10" which is loads of room to swing your soldering around under and it's a much more comfortable height to be working at. The 'down side' to equipment at this price range is the fact that you do only have 10x and 20x fixed magnification. This is still fantastic though and I can't really see me needing any further magnification range or adjustment at this time. If you want to go down that route you're looking at something like the [Amscope SM-4B] that has adjustable 7x-45x magnification but it's also 2x the price. Maybe an upgrade for further down the line if required.....

Anyway, I digress. Using a microscope like this makes everything so much easier. I've never soldered any SMD stuff before and this made it a breeze, it almost feels like cheating

Initially, I had a TS-100 soldering iron with a stock TS-B2 tip and I only had some 1mm(0.040") solder as that's what I've generally been using for my cable assembly soldering. I did use these for a start to see how I got on and to be honest, I managed 'ok' with them. This is the stock TS-B2 tip and 1mm solder next to a 0402:

As you can see, the solder is pretty huge in comparison to the components and the iron tip isn't much better. I did manage to solder with these but it was hard to control the amount of solder and get nice concave joints. Even just tinning the stock tip put too much solder on for a 0402 component.

I picked up a TS-I tip for the TS-100 and I also bought some 0.38mm (0.015") and some 0.25mm (0.010") 63/37 leaded solder.

For comparison this is a TS-BC2 tip, the stock TS-B2 tip and the TS-I tip:

This is the 1mm solder, 0.38mm solder and 0.25mm solder:

There's not a massive difference between the 0.38mm and the 0.25mm solder in terms of usability. The 0.25 is a little more controllable but it does seem to be much harder to come by than the 0.38mm/0.4mm solder. If you can only get 0.38/0.4mm then that should be fine.

Just for comparison again, here's the 0402 resistors next to the TS-I tip and the 0.25mm solder:

I found the TS-I tip with it 0.2mm radius much easier to use and the finer solder made it much easier to apply an exact amount of solder. I know some people prefer the stock tip for micro soldering but I much prefer the finer one.

Side note: I picked up a [2UUL Universal Double Shaft High Temperature PCB Board Holder Fixture] which is ideal for this type of thing and should come in useful for lots of projects:

So my next step is to pick up some 0201 components and a test board. I'm pretty confident that I can do this install though after this bit of practice. If anyone is wanting to do this to their switch I would at least recommend picking up a practice board and trying out your soldering on that before attacking your switch. Most of the install videos I have seen so far have made me wince!

If I can give any other advice it would be:

Clean everything with IPA before starting.

Make sure you use flux, and use it often.

Watch your temps and solder time. You are better off using a higher heat for a short period of time than a lower temp for a longer period. Once again, practice.

Normally I pre-tin everything prior to bringing parts together and soldering but looking at the videos I have seen so far I think I'm going to get everything into position and then pre-tin the pads and then solder at the same time on this particular installation.

Hope that helps a little. I'm looking forward to the install once the chips are available!

Hi,

Since txswitch doesn't take preorder anymore, do you have other retailers with (relatively) good prices?

I only saw a few retailers asking more than 150$ for the preorders (trusted retailers according to TX).

Thanks

Since txswitch doesn't take preorder anymore, do you have other retailers with (relatively) good prices?

I only saw a few retailers asking more than 150$ for the preorders (trusted retailers according to TX).

Thanks

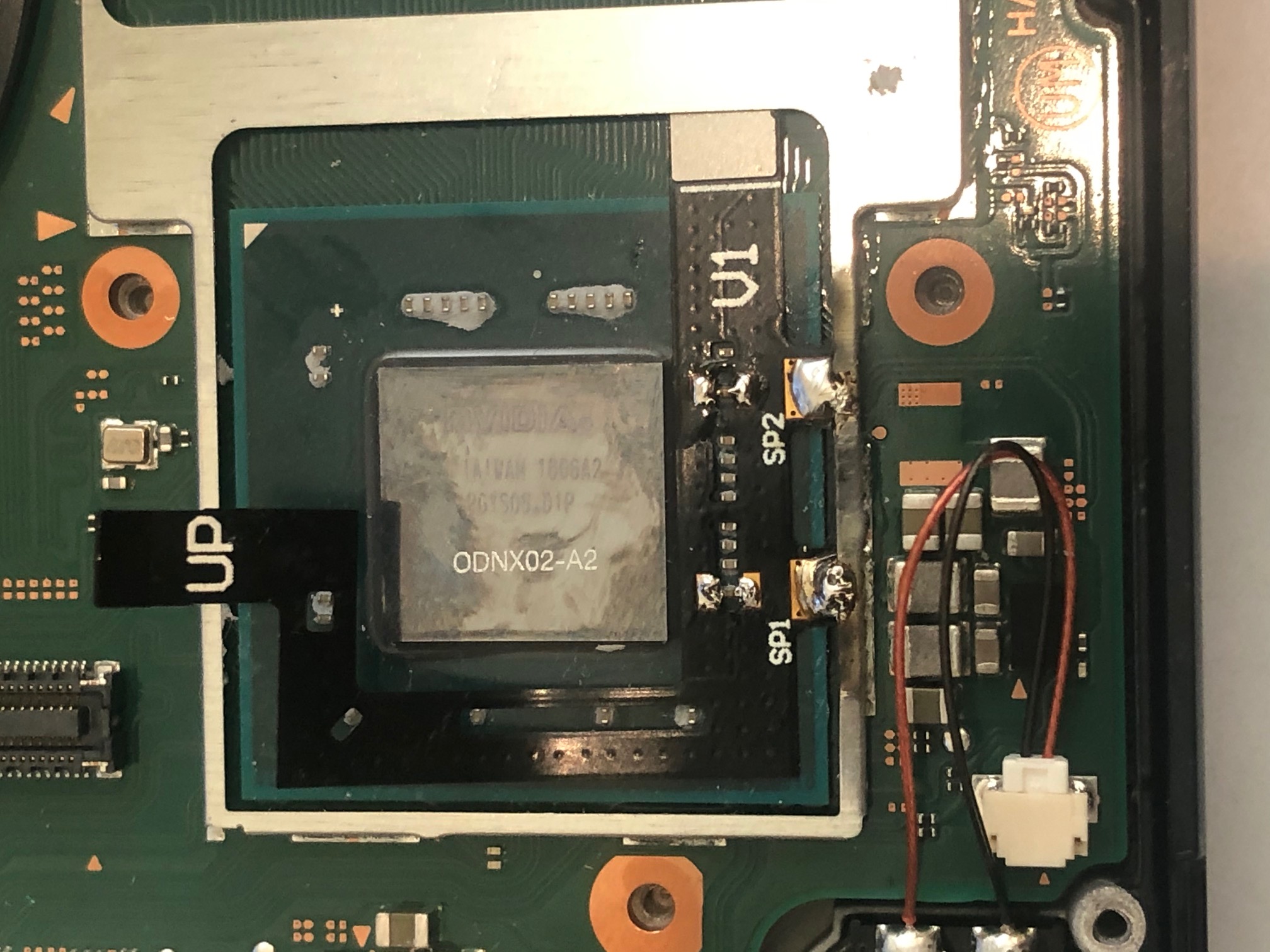

When you put it back together, where did you redo the thermal paste? The chip of course but did you cover the caps too or other places?Installed mine today in about an hour. Soldering took about 15 min using a cheap iron and $10 jewelers glasses. But I use to install original 30 wire xbox chips, so this was easy even with my now bad vision and shaking hands.

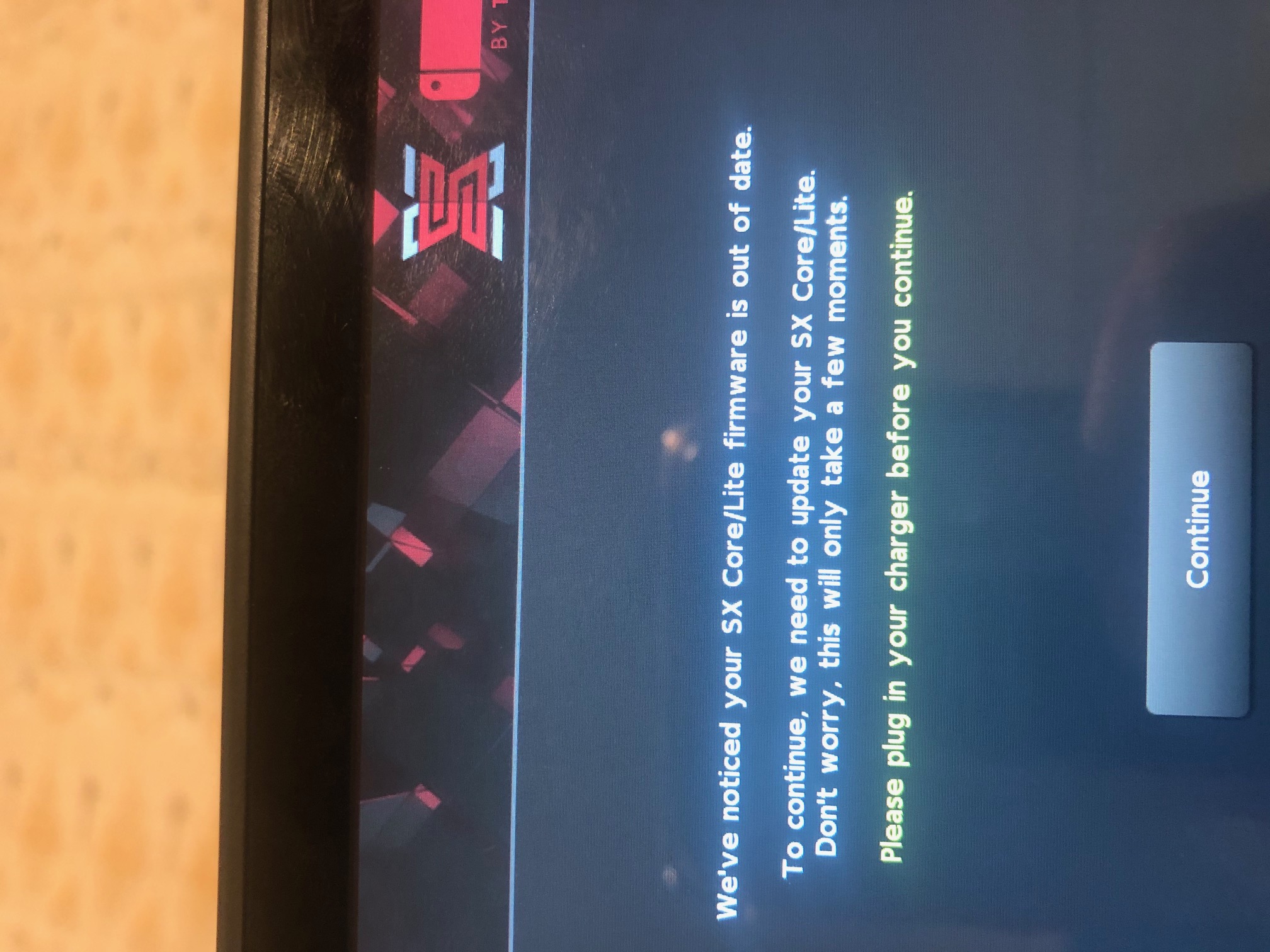

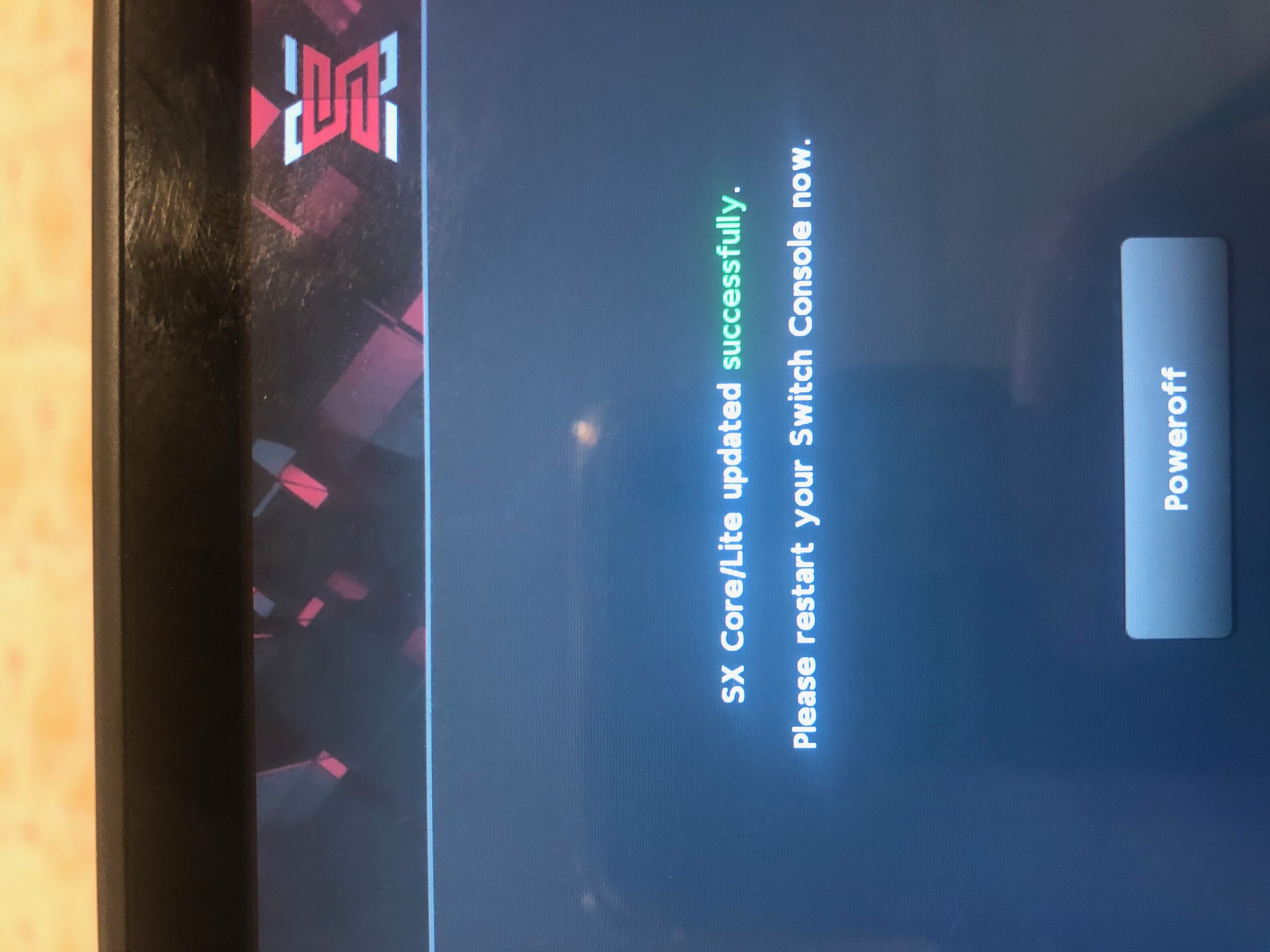

View attachment 213170 View attachment 213171 View attachment 213172 View attachment 213173

You only need thermal compound on the chip die and the place where the heatpipes touch the chip shielding. The excess paste all over the caps is just a result of Nintendo applying too much of it.When you put it back together, where did you redo the thermal paste? The chip of course but did you cover the caps too or other places?

When you put it back together, where did you redo the thermal paste? The chip of course but did you cover the caps too or other places?

When you apply paste, make sure you have enough to cover the whole die and any areas where the hear pipes touch the shielding, just like Diskun said. It'll probably squeeze out and cover the caps around the die when you screw in the heat sink, but that's fine. It's better to put more paste and be certain that the surfaces are properly covered than to not have enough and leave some of the die uncovered, just make sure you use paste that's non-conductive electrically.You only need thermal compound on the chip die and the place where the heatpipes touch the chip shielding. The excess paste all over the caps is just a result of Nintendo applying too much of it.

I see.. and they also raised the prices

u guys know any shop aliexpress or chine based

just search sx lite and you'll find one. I bought one sx core in aliexpress. It's easy to get a refund just in case it turns out to be a scam or not in aliexpress.u guys know any shop aliexpress or chine based

thank you for answer.just search sx lite and you'll find one. I bought one sx core in aliexpress. It's easy to get a refund just in case it turns out to be a scam or not in aliexpress.

can u give me link sx core seller. ı cant find

I thought I would share my progress so far with my preparation for this install.

I've been soldering for years but I've never done any SMD work, tiny or otherwise. It's something I've always wanted to do and I figured this would be a good time to learn a new skill and pick up some new kit.

The first thing I did was to pick up a practice SMD soldering board from ebay to see what kinda components I was dealing with. I got one of the 'blue' kits as they allowed you to practice with a decent range of package sizes down to 0402. I didn't know the switch capacitors were 0201 at the time, I'm going to look for a practice board with those on next. This is the blue practice board kit:

To get a scale of size, this is a MicroSD card and a grain of rice in comparison to the 0402 resistors...and bare in mind that the 0201 resistors are even smaller than that. I've posted Theorem's picture below for comparison again:

It was pretty obvious that I'm not going to be able to do this without some kind of magnification. I had previously tried using a 1x-14x head mounted magnifying visor in the past but I just couldn't get on with it. The main problem was the focal length. The greater the magnification, the smaller the focal length was. If I was using the higher end of the magnification the focal length was only a couple of inches which meant your head/lenses were right near the part and you risked stabbing yourself in the cheek with your ironI know people do use these and use them well but they're just not for me.

After a lot of research looking into various types of magnification I decided that a stereo microscope was most likely going to give the best results. There are not too many choices for stereo microscopes. It seems to be either mid range hobby level or top end pro level. I opted for the former and bought a

I've got to say, equipment-wise this is one of the best things I've ever bought. It comes with 10x and 20x lenses, so far I've been doing everything with the 10x lenses which is more than adequate for 0402 and I imagine 0201 would be fine too, if not the 20x would certainly cover it. The two goose neck lights are great too but the best thing about this kind of magnification is the focal length! It's about 250mm/10" which is loads of room to swing your soldering around under and it's a much more comfortable height to be working at. The 'down side' to equipment at this price range is the fact that you do only have 10x and 20x fixed magnification. This is still fantastic though and I can't really see me needing any further magnification range or adjustment at this time. If you want to go down that route you're looking at something like the that has adjustable 7x-45x magnification but it's also 2x the price. Maybe an upgrade for further down the line if required.....

Anyway, I digress. Using a microscope like this makes everything so much easier. I've never soldered any SMD stuff before and this made it a breeze, it almost feels like cheating

Initially, I had a TS-100 soldering iron with a stock TS-B2 tip and I only had some 1mm(0.040") solder as that's what I've generally been using for my cable assembly soldering. I did use these for a start to see how I got on and to be honest, I managed 'ok' with them. This is the stock TS-B2 tip and 1mm solder next to a 0402:

As you can see, the solder is pretty huge in comparison to the components and the iron tip isn't much better. I did manage to solder with these but it was hard to control the amount of solder and get nice concave joints. Even just tinning the stock tip put too much solder on for a 0402 component.

I picked up a TS-I tip for the TS-100 and I also bought some 0.38mm (0.015") and some 0.25mm (0.010") 63/37 leaded solder.

For comparison this is a TS-BC2 tip, the stock TS-B2 tip and the TS-I tip:

This is the 1mm solder, 0.38mm solder and 0.25mm solder:

There's not a massive difference between the 0.38mm and the 0.25mm solder in terms of usability. The 0.25 is a little more controllable but it does seem to be much harder to come by than the 0.38mm/0.4mm solder. If you can only get 0.38/0.4mm then that should be fine.

Just for comparison again, here's the 0402 resistors next to the TS-I tip and the 0.25mm solder:

und the TS-I tip with it 0.2mm radius much easier to use and the finer solder made it much easier to apply an exact amount of solder. I know some people prefer the stock tip for micro soldering but I much prefer the finer one.

Side note: I picked up a which is ideal for this type of thing and should come in useful for lots of projects:

So my next step is to pick up some 0201 components and a test board. I'm pretty confident that I can do this install though after this bit of practice. If anyone is wanting to do this to their switch I would at least recommend picking up a practice board and trying out your soldering on that before attacking your switch. Most of the install videos I have seen so far have made me wince!

If I can give any other advice it would be:

Clean everything with IPA before starting.

Make sure you use flux, and use it often.

Watch your temps and solder time. You are better off using a higher heat for a short period of time than a lower temp for a longer period. Once again, practice.

Normally I pre-tin everything prior to bringing parts together and soldering but looking at the videos I have seen so far I think I'm going to get everything into position and then pre-tin the pads and then solder at the same time on this particular installation.

Hope that helps a little. I'm looking forward to the install once the chips are available!

To be honest, you are overthinking it. It's kind of simple to do. The most important thing is to line it up properly and soldering the anchor points. After that it's cake. Like I was saying, I was using cheap jewelers glasses and one eye closed. Also for me silver bearing core solder worked better and some old flux paste I had laying around.

--------------------- MERGED ---------------------------

When you boot it up, it will create a licence request file, you can upload that file to the SX site to generate a license file you download and put on the SD card, or you can activate right from the switch if it's connected with WiFi.Do the versions of sx core sold on AliExpress also come with the sx licence? How does it even work for the core, is it baked in the hardware or you get the code via email?

Oh yeah, this. This is worth noting. Do not use Thermal Grizzly Conductonaut (or any other Liquid Metal) just because it is the best stuff. If you put liquid metal on the die and it goes down to the caps or really any contact in there, your Switch is toast.When you apply paste, make sure you have enough to cover the whole die and any areas where the hear pipes touch the shielding, just like Diskun said. It'll probably squeeze out and cover the caps around the die when you screw in the heat sink, but that's fine. It's better to put more paste and be certain that the surfaces are properly covered than to not have enough and leave some of the die uncovered, just make sure you use paste that's non-conductive electrically.

Oh yeah, this. This is worth noting. Do not use Thermal Grizzly Conductonaut (or any other Liquid Metal) just because it is the best stuff. If you put liquid metal on the die and it goes down to the caps or really any contact in there, your Switch is toast.

Well no use liquid metal, but I'm gonna use thermal conductive.. As long this paste doesn't toch the capacitor, everything will be fine

Thermal paste is expected to be thermally conductive. What you shouldn't use is stuff that conducts electricity as well. Some pastes like earlier versions of Arctic Silver 5 have particles of electrically conductive materials in their composition, usually silver or graphite. Most products nowadays, like MX-4 and Kryonaut don't have that, and can touch components without any issue.Well no use liquid metal, but I'm gonna use thermal conductive.. As long this paste doesn't toch the capacitor, everything will be fine

I have kryonaut and it works wonderful on everything I've used it on. I used to use gelid extreme

Applies better and doesn't dry out as early.

Gelid after 2 years did just kinda go blah on my ryzen.

kyronaut has been wonderful on air and watercooling on pc and laptops. I'm hoping on the switch it'll be good too.

Applies better and doesn't dry out as early.

Gelid after 2 years did just kinda go blah on my ryzen.

kyronaut has been wonderful on air and watercooling on pc and laptops. I'm hoping on the switch it'll be good too.

Last edited by caldeio,

I'm installing the SX Core with a 10usd soldering iron and a bunch of liquid flux. Praying that I don't f*** up my console. I practiced on an old xbox 360 board.

Wish me luck on my dumb idea/attempt.

Wish me luck on my dumb idea/attempt.

You can get a variable temp soldering iron from Amazon for $35. I would get that and cheap head band magnifier. Make it a ton easier and improve your chances.I'm installing the SX Core with a 10usd soldering iron and a bunch of liquid flux. Praying that I don't f*** up my console. I practiced on an old xbox 360 board.

Wish me luck on my dumb idea/attempt.

Thermal paste is expected to be thermally conductive. What you shouldn't use is stuff that conducts electricity as well. Some pastes like earlier versions of Arctic Silver 5 have particles of electrically conductive materials in their composition, usually silver or graphite. Most products nowadays, like MX-4 and Kryonaut don't have that, and can touch components without any issue.

I use Kryonaut But I think it's conductive

PD: Oh I see it's dielectric..fine

Last edited by Astur_torque,

Similar threads

- Replies

- 0

- Views

- 2K

- Replies

- 4

- Views

- 946

- Replies

- 300

- Views

- 80K

-

- Article

- Replies

- 12

- Views

- 5K

- Replies

- 4

- Views

- 4K

Site & Scene News

New Hot Discussed

-

-

57K views

Nintendo Switch firmware 18.0.0 has been released

It's the first Nintendo Switch firmware update of 2024. Made available as of today is system software version 18.0.0, marking a new milestone. According to the patch... -

28K views

GitLab has taken down the Suyu Nintendo Switch emulator

Emulator takedowns continue. Not long after its first release, Suyu emulator has been removed from GitLab via a DMCA takedown. Suyu was a Nintendo Switch emulator... -

20K views

Atmosphere CFW for Switch updated to pre-release version 1.7.0, adds support for firmware 18.0.0

After a couple days of Nintendo releasing their 18.0.0 firmware update, @SciresM releases a brand new update to his Atmosphere NX custom firmware for the Nintendo...by ShadowOne333 94 -

18K views

Wii U and 3DS online services shutting down today, but Pretendo is here to save the day

Today, April 8th, 2024, at 4PM PT, marks the day in which Nintendo permanently ends support for both the 3DS and the Wii U online services, which include co-op play...by ShadowOne333 176 -

16K views

Denuvo unveils new technology "TraceMark" aimed to watermark and easily trace leaked games

Denuvo by Irdeto has unveiled at GDC (Game Developers Conference) this past March 18th their brand new anti-piracy technology named "TraceMark", specifically tailored...by ShadowOne333 101 -

15K views

GBAtemp Exclusive Introducing tempBOT AI - your new virtual GBAtemp companion and aide (April Fools)

Hello, GBAtemp members! After a prolonged absence, I am delighted to announce my return and upgraded form to you today... Introducing tempBOT AI 🤖 As the embodiment... -

12K views

Pokemon fangame hosting website "Relic Castle" taken down by The Pokemon Company

Yet another casualty goes down in the never-ending battle of copyright enforcement, and this time, it hit a big website which was the host for many fangames based and...by ShadowOne333 65 -

11K views

MisterFPGA has been updated to include an official release for its Nintendo 64 core

The highly popular and accurate FPGA hardware, MisterFGPA, has received today a brand new update with a long-awaited feature, or rather, a new core for hardcore...by ShadowOne333 51 -

11K views

Apple is being sued for antitrust violations by the Department of Justice of the US

The 2nd biggest technology company in the world, Apple, is being sued by none other than the Department of Justice of the United States, filed for antitrust...by ShadowOne333 80 -

10K views

Homebrew SpotPass Archival Project announced

With Nintendo ceasing online communication for Nintendo 3DS, 2DS and Wii U systems next month, SpotPass data distribution will be halted. This will in turn affect...

-

-

-

223 replies

Nintendo Switch firmware 18.0.0 has been released

It's the first Nintendo Switch firmware update of 2024. Made available as of today is system software version 18.0.0, marking a new milestone. According to the patch...by Chary -

176 replies

Wii U and 3DS online services shutting down today, but Pretendo is here to save the day

Today, April 8th, 2024, at 4PM PT, marks the day in which Nintendo permanently ends support for both the 3DS and the Wii U online services, which include co-op play...by ShadowOne333 -

169 replies

GBAtemp Exclusive Introducing tempBOT AI - your new virtual GBAtemp companion and aide (April Fools)

Hello, GBAtemp members! After a prolonged absence, I am delighted to announce my return and upgraded form to you today... Introducing tempBOT AI 🤖 As the embodiment...by tempBOT -

146 replies

GitLab has taken down the Suyu Nintendo Switch emulator

Emulator takedowns continue. Not long after its first release, Suyu emulator has been removed from GitLab via a DMCA takedown. Suyu was a Nintendo Switch emulator...by Chary -

101 replies

Denuvo unveils new technology "TraceMark" aimed to watermark and easily trace leaked games

Denuvo by Irdeto has unveiled at GDC (Game Developers Conference) this past March 18th their brand new anti-piracy technology named "TraceMark", specifically tailored...by ShadowOne333 -

95 replies

The first retro emulator hits Apple's App Store, but you should probably avoid it

With Apple having recently updated their guidelines for the App Store, iOS users have been left to speculate on specific wording and whether retro emulators as we...by Scarlet -

94 replies

Atmosphere CFW for Switch updated to pre-release version 1.7.0, adds support for firmware 18.0.0

After a couple days of Nintendo releasing their 18.0.0 firmware update, @SciresM releases a brand new update to his Atmosphere NX custom firmware for the Nintendo...by ShadowOne333 -

80 replies

Apple is being sued for antitrust violations by the Department of Justice of the US

The 2nd biggest technology company in the world, Apple, is being sued by none other than the Department of Justice of the United States, filed for antitrust...by ShadowOne333 -

65 replies

Pokemon fangame hosting website "Relic Castle" taken down by The Pokemon Company

Yet another casualty goes down in the never-ending battle of copyright enforcement, and this time, it hit a big website which was the host for many fangames based and...by ShadowOne333 -

52 replies

Nintendo "Indie World" stream announced for April 17th, 2024

Nintendo has recently announced through their social media accounts that a new Indie World stream will be airing tomorrow, scheduled for April 17th, 2024 at 7 a.m. PT...by ShadowOne333

-

Popular threads in this forum

General chit-chat

-

The Real Jdbye

Loading…*is birb*

The Real Jdbye

Loading…*is birb*

-

@

Psionic Roshambo:

So my opinion is that they could age a bit better in the future, and maybe AMD will continue improving them via drivers like they tend to do. No guarantee there but they have done it in the past. Just a feeling I have.

@

Psionic Roshambo:

So my opinion is that they could age a bit better in the future, and maybe AMD will continue improving them via drivers like they tend to do. No guarantee there but they have done it in the past. Just a feeling I have. -

-

-

-

@

The Real Jdbye:

they definitely will age better but i feel dlss might outweigh that since it looks about as good as native resolution and much less demanding+1

@

The Real Jdbye:

they definitely will age better but i feel dlss might outweigh that since it looks about as good as native resolution and much less demanding+1 -

-

@

The Real Jdbye:

AMD could introduce something comparable to DLSS but nvidia's got a lot more experience with that

@

The Real Jdbye:

AMD could introduce something comparable to DLSS but nvidia's got a lot more experience with that -

@

The Real Jdbye:

least amd 7xxx has tensor cores which the previous generations didn't so there is the potential for AI upscaling

@

The Real Jdbye:

least amd 7xxx has tensor cores which the previous generations didn't so there is the potential for AI upscaling -

-

-

-

-

-

-

@

The Real Jdbye:

i think i heard of that, it's a good idea, shouldn't need a dedicated GPU just to run a LLM or video upscaling

@

The Real Jdbye:

i think i heard of that, it's a good idea, shouldn't need a dedicated GPU just to run a LLM or video upscaling -

-

-

@

BakerMan:

Have you ever been beaten by a wet spaghetti noodle by your girlfriend because she has a twin sister, and you got confused and fucked her dad?

@

BakerMan:

Have you ever been beaten by a wet spaghetti noodle by your girlfriend because she has a twin sister, and you got confused and fucked her dad? -

-

@

Psionic Roshambo:

I had a girlfriend who had a twin sister and they would mess with me constantly.... Until one chipped a tooth then finally I could tell them apart.... Lol

@

Psionic Roshambo:

I had a girlfriend who had a twin sister and they would mess with me constantly.... Until one chipped a tooth then finally I could tell them apart.... Lol -

@

Psionic Roshambo:

They would have the same hair style the same clothes everything... Really messed with my head lol

@

Psionic Roshambo:

They would have the same hair style the same clothes everything... Really messed with my head lol -

@

Psionic Roshambo:

@The Real Jdbye, I could see AMD trying to pull off the CPU GPU tandem thing, would be a way to maybe close the gap a bit with Nvidia. Plus it would kinda put Nvidia at a future disadvantage since Nvidia can't make X86/64 CPUs? Intel and AMD licensing issues... I wonder how much that has held back innovation.

@

Psionic Roshambo:

@The Real Jdbye, I could see AMD trying to pull off the CPU GPU tandem thing, would be a way to maybe close the gap a bit with Nvidia. Plus it would kinda put Nvidia at a future disadvantage since Nvidia can't make X86/64 CPUs? Intel and AMD licensing issues... I wonder how much that has held back innovation. -

-

-