The usual cowboy cheat way is to upturn a thing of canned air and spray it on the potentially misbehaving chip or device. Can narrow down which chip is causing the problem.Is their anyway to add temporary extra source of colding and see if makes any difference? At least so OP can test it out.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Jun 4, 2015

- Messages

- 1,441

- Trophies

- 1

- Location

- Minus World

- Website

- www.youtube.com

- XP

- 2,481

- Country

Check under Settings > Support > Error HistoryCrash logs? I just had every option in my Switch examined twice but did not find that?

I finally found the time to read through all the new replies, im quite surprised there are so many!

Alright, lets begin with what I tried today.

@LineoftheDead I measured continuity between pin 4 (XRST) and the capacitor with the light color 2 components to the right of the missing one. Continuity was present between those points, so you are right. However I tried soldering on wires from where toe original resistor was and then attached a potentiometer up to it which I then set to around 100k Ohms, so it should have done the job, right? Or perhaps the potentiometer was a little inaccurate? I dont think an additional 0.5k Ohms more or less would make a huge difference on the potentiometer.

Also, I could not find any chips that are getting hot while the switch is running, so I do not think overheating is the issue here. IPA did not evaporate off of any chips instantly, and I can barely feel heat on any chips anyways. The back side of the mainboard also does not have any overheating ICs.

@FAST6191 Claiming warranty on the thing will mostly fail, I already left my marks everywhere (including stripped screws that I cannot use anymore etc.)

As already mentioned above, I cannot find any overheating components on the board while its running or while it froze. It could very well be some bad solder joints that "shrink" back together after one night so they work for quite some time and the more often I reboot the system all the time the less time it actually lasts. Its as if the thing is sort of regenerating itself during the night when its not being experimented on by me. Reflowing, as others mentioned, could really be the way to go here, but apart from the reason that I dont (yet) have a way of doing that, I would like to keep the reflow method as a last resort for now. I also do not have a lab bench power supply so i cant really try powering the device like that, but with that logic the same is probably going to happen. Speaking of power, what do you think the grey cable of the battery is for? It sometimes measures odd Voltages to ground, so I am wondering what that could be for, maybe this is what is providing some sort of data to the switch that causes it to freeze? Anyways, it turns out I do indeed have the M92T model of the IC as the A model has been released after the switch was in production. Still, I do not quite understand the purpose of XRST and VSTR yet, or if it has in any way something to do with the not-actively-updating battery percentage during when the console is running?

My potentiometer that I attached to where the original resistor was read 100k Ohms, exactly like the one that should have been on the spot. I also checked with my multimeter to see if the resistance was right, and the pot only varied in about 0.5k Ohms. Surely that wont be enough to keep the thing from not working at all, but I might try it with the pot again if you think the resistor value has to be a lot more precise. Still, 99.5k - 100.5k Ohms should have worked if the missing resistor was the problem.

@Futurdreamz See above. It is probably not a heat issue, I cannot find any chips that seem to get hot while the console is running. Though there might be a faulty chip that is failing at fairly low warm temperatures already. Im probably going to have to test that out a little more.

@B4rtj4h I dont have an IR cam, but the mainboard is not overheating anywhere at all, like you can read above the worst it could be is a faulty chip that misbehaves even on low warm temps. Also to clarify: It also freezes when playing games, it does not matter what I do. I also initialized the console again, but it still freezes, so It is not some sort of corrupt software.

@NekoMichi The crash logs or rather "Last error messages" just show some errors that I got because of other reasons like because it couldnt connect to the eShop because I did not set up the Wifi.

Also a little update:

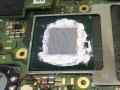

I tried unplugging everything that was not needed to run the console, that means one of the joycon connectors, any antenna cables, the display cables, the digitizer and cartridge reader cable, and anything else besides the backlight cable, one speaker cable and the battery wires. I could hear when the switch froze when I noticed that the menu did not make any more clicking sounds when using the controller to browse the main menu and selecting things. I have also replaced the thermal paste behind the cpu shield now (see attached pictures), and while I was at it I checked whether the DRAM next to the cpu or the cpu itself got hot while running the switch, and again, they did not. I put the cpu shield back on again.

Also I will be receiving the charging adapter for the switch dock (which was not included so I had to buy one) in 10 Hours, perhaps I can dock the switch into TV mode and see if it freezes then as well. Perhaps in docked mode power distribution and all of that behaves differently. And lastly, as many have already suggested, if this project goes nowhere, I will eventually try reflowing the mainboardl, but lets not consider this method just yet.

In the meantime I will be trying to find a little 100k Ohm resistor to put on the place where the missing one now is, if I just knew the package size those tiny resistors are.

Anyways, hope this was informative, perhaps we can sooner or later find the problem.

And as usualy, thanks for any help!

Alright, lets begin with what I tried today.

can you test continuity, pin 4 to the capacitor (2 over from the missing resistor). if you get teh beep beeps then you should scroll to page 26. VCCIN to VSTR/ATST2 to XRST (Digital block Reset). you really just want to throw that resistor back on there. best way to do it --> flux and leaded solder the pads, then wick them clean. flux the now clean pads, hold the resistor on the pads with tweezers (just apply pressure in the middle, on the top), tin a chisel tip and hit both pads at the same time (you have a perfect angle to do this)

--------------------- MERGED ---------------------------

oh yeah, you should read page 27 as well. btw, does this IC get hot fast? run down to fred meyers and buy some 99% IPA, cover the chip with it and power on the device, see if it instantly evaporates

@LineoftheDead I measured continuity between pin 4 (XRST) and the capacitor with the light color 2 components to the right of the missing one. Continuity was present between those points, so you are right. However I tried soldering on wires from where toe original resistor was and then attached a potentiometer up to it which I then set to around 100k Ohms, so it should have done the job, right? Or perhaps the potentiometer was a little inaccurate? I dont think an additional 0.5k Ohms more or less would make a huge difference on the potentiometer.

Also, I could not find any chips that are getting hot while the switch is running, so I do not think overheating is the issue here. IPA did not evaporate off of any chips instantly, and I can barely feel heat on any chips anyways. The back side of the mainboard also does not have any overheating ICs.

@DeadlyFoez I do not think this is an issue with overheating, as, with already mentioned above, no chips get hot at all. Still, strangely enough when I first boot the console on a new day it lasts for a couple minutes, but the more I repeat unplugging the battery and trying to boot up the console the shorter it lasts in newer attempts. Perhaps something is actually cooling down or making contact again during the night? Reflowing would certainly fix any bad solder connections especially on bga chips, but firstly I do not have a reflow oven (only a traditional baking oven for... well... cooking?) and seconly I would like to keep this attempt to fix the issue as a last escape in case everything else fails. I am concerned about any plastic connectors on the board though, wouldnt they melt off while reflowing?I would try reflowing the whole pcb and add a little flux. Sounds like a heat related issue to me, if not then i would call it as being faulty chips with micro fractures.

You can still try claiming the warranty on it. Assuming you did not break any seals or mar the insides then it is all good. I am not sure of the complete electronics warranty laws of Germany but they are typically in line with much of Europe which often has rulings like "if it was not something you screwed up then it plays, car warranties typically being this -- your nitrous kit might destroy your engine but they still get to fix your boot latch and they can't write the whole thing off). I would also struggle to see an ethical issue as well.

Having to pull power or run down the battery is nothing unusual on modern systems -- so many only have software controlled power buttons.

Something being measured in the minutes is either something overheating or something which only kicks in long after initialisation. You can try to narrow that down by idling in a low activity menu with wifi off and all that vs jumping right into a game and having all CGI intro and whatnot, as well as immediately powering back on after unplugging the battery before it has a chance to really cool back down. Let's not go into the freeze spray fixing methods just yet, not least of all because that is trickier on security focused devices that tend to lock up on exceptions.

We don't really know the switch boot path and how many services they might have stuck a delay on, though your battery concerns might be that.

If you have a thermal camera or maybe a laser thermometer you can try to see any heat build up.

On to the battery stuff mentioned. Makes sense. I have yet to read the datasheet for the IC but if you have a stabilised bench supply then I might consider bypassing that. However if it is expecting some kind of data signal out of the IC to inform the firmware you might also be lumped recreating that. Likely something you could fake with a microcontroller but cross that bridge as and when.

Edit. Started reading the datasheet.

Looks like you have the M92A family where this says M92T36. I could not find 36 but there was 30 [Had to remove link because spam or something]

The marking pages are not helpful in telling me what the differences might be so this is still an unknown. The difference between the 56 and the 50 is in supply voltage (not looked at the sheets yet).

The typical application circuit varies on this pin as well, the A family having no resistor where the T does, though in both cases go to VCCin. Right now I don't know what that might do as far as cooking it (if it is extreme cases current limiting then that is one thing, if it is more a fusible link then that is another and if it is general limiting that is another still). Said application circuits have 100KOhm resistors there, and the internal equivalent circuit for the pin do not all have resistors on them. If your pot was not in the 100K range then maybe go back and take a look.

@FAST6191 Claiming warranty on the thing will mostly fail, I already left my marks everywhere (including stripped screws that I cannot use anymore etc.)

As already mentioned above, I cannot find any overheating components on the board while its running or while it froze. It could very well be some bad solder joints that "shrink" back together after one night so they work for quite some time and the more often I reboot the system all the time the less time it actually lasts. Its as if the thing is sort of regenerating itself during the night when its not being experimented on by me. Reflowing, as others mentioned, could really be the way to go here, but apart from the reason that I dont (yet) have a way of doing that, I would like to keep the reflow method as a last resort for now. I also do not have a lab bench power supply so i cant really try powering the device like that, but with that logic the same is probably going to happen. Speaking of power, what do you think the grey cable of the battery is for? It sometimes measures odd Voltages to ground, so I am wondering what that could be for, maybe this is what is providing some sort of data to the switch that causes it to freeze? Anyways, it turns out I do indeed have the M92T model of the IC as the A model has been released after the switch was in production. Still, I do not quite understand the purpose of XRST and VSTR yet, or if it has in any way something to do with the not-actively-updating battery percentage during when the console is running?

My potentiometer that I attached to where the original resistor was read 100k Ohms, exactly like the one that should have been on the spot. I also checked with my multimeter to see if the resistance was right, and the pot only varied in about 0.5k Ohms. Surely that wont be enough to keep the thing from not working at all, but I might try it with the pot again if you think the resistor value has to be a lot more precise. Still, 99.5k - 100.5k Ohms should have worked if the missing resistor was the problem.

It does sound like a heat issue. Are all chips in proper contact with the heatsink? There may be more than one, and if they have been cleaned they may not have the right amount of thermal paste.

@Futurdreamz See above. It is probably not a heat issue, I cannot find any chips that seem to get hot while the console is running. Though there might be a faulty chip that is failing at fairly low warm temperatures already. Im probably going to have to test that out a little more.

I would suggest on the moment of hang up try to see with an IR cam if it is overheated... because your symptoms don't exactly specify overheating issues. Nvidia stuff always starts with artefacts when they overheat... OP did not mention that just yet.

Another thought: did you test if the same happens when not playing a game? And did you reinstall the console?

@B4rtj4h I dont have an IR cam, but the mainboard is not overheating anywhere at all, like you can read above the worst it could be is a faulty chip that misbehaves even on low warm temps. Also to clarify: It also freezes when playing games, it does not matter what I do. I also initialized the console again, but it still freezes, so It is not some sort of corrupt software.

Check the crash logs, see if it mentions kernel panics (?) or something. I remember a while back trying to repair a phone with a similar issue, turned out the terminal of the battery pack that communicates the temperature had failed, so the OS kept trying to get that data and would shut down for safety reasons after a certain number of failed attempts. Of course, your issue might be different entirely but crash logs could provide some useful information.

@NekoMichi The crash logs or rather "Last error messages" just show some errors that I got because of other reasons like because it couldnt connect to the eShop because I did not set up the Wifi.

Also a little update:

I tried unplugging everything that was not needed to run the console, that means one of the joycon connectors, any antenna cables, the display cables, the digitizer and cartridge reader cable, and anything else besides the backlight cable, one speaker cable and the battery wires. I could hear when the switch froze when I noticed that the menu did not make any more clicking sounds when using the controller to browse the main menu and selecting things. I have also replaced the thermal paste behind the cpu shield now (see attached pictures), and while I was at it I checked whether the DRAM next to the cpu or the cpu itself got hot while running the switch, and again, they did not. I put the cpu shield back on again.

Also I will be receiving the charging adapter for the switch dock (which was not included so I had to buy one) in 10 Hours, perhaps I can dock the switch into TV mode and see if it freezes then as well. Perhaps in docked mode power distribution and all of that behaves differently. And lastly, as many have already suggested, if this project goes nowhere, I will eventually try reflowing the mainboardl, but lets not consider this method just yet.

In the meantime I will be trying to find a little 100k Ohm resistor to put on the place where the missing one now is, if I just knew the package size those tiny resistors are.

Anyways, hope this was informative, perhaps we can sooner or later find the problem.

And as usualy, thanks for any help!

Attachments

Nooooo. I never said anything about overheating. It obviously is not overheating. Take a class on thermal dynamics and then come back to us. You obviously do not understand how heat makes materials expand and even a few degrees can separate weak joints.

You cover all plastic parts with foil or kapton tape. It is simple to do. Even a heat gun can reflow if you are careful enough.

You cover all plastic parts with foil or kapton tape. It is simple to do. Even a heat gun can reflow if you are careful enough.

Last edited by DeadlyFoez,

Yeah dude I'll be swinging by my work tomorrow - got a whole rack of small components I ordered off mouser | ill take reference pictures of all my differing packing sizes for you. I have never used a potentiometer but I can tell you I dont like those squirrely wires. you have two sensors on that VCCIN line and im thinking not having that resistor in place would cause an issue. my only sensor experience was related to a backlight circuit, when probing voltage on a resistor in this line (that feeds to ground), the sensor would send the enable signal and, thus, send backlight to the LVDS. But it just goes to show you how sensitive sensors can be.

I do a lot of microsoldering on various products. having schematics available turn a 8 hr job into a 30 minute job, I totally understand your frustration. It should be noted (not that I think it matters), that I am a monkey at understanding circuits. I get the job done though ;D

I do a lot of microsoldering on various products. having schematics available turn a 8 hr job into a 30 minute job, I totally understand your frustration. It should be noted (not that I think it matters), that I am a monkey at understanding circuits. I get the job done though ;D

Nooooo. I never said anything about overheating. It obviously is not overheating. Take a class on thermal dynamics and then come back to us. You obviously do not understand how heat makes materials expand and even a few degrees can separate weak joints.

You cover all plastic parts with foil or kapton tape. It is simple to do. Even a heat gun can reflow if you are careful enough.

I am aware of the effects of thermal expansion of materials, and it might be a good reason why a specific soler joint looses contact when the chip expands. This does not mean there is no internal fault with any of the chips. But still, reflowing at this point would at least be worth trying. Luckily I have bought myself the tools needed for microsoldering and hot air soldering a while back, so I could try reflowing some of the larger chips. I doubt the heat gun with the largest nozzle is capable of reflowing the largest of chips like the main Processor though? In that case using some sort of reflow oven would be much better.

I'll do some research and determine which method would be better.

Yeah dude I'll be swinging by my work tomorrow - got a whole rack of small components I ordered off mouser | ill take reference pictures of all my differing packing sizes for you. I have never used a potentiometer but I can tell you I dont like those squirrely wires. you have two sensors on that VCCIN line and im thinking not having that resistor in place would cause an issue. my only sensor experience was related to a backlight circuit, when probing voltage on a resistor in this line (that feeds to ground), the sensor would send the enable signal and, thus, send backlight to the LVDS. But it just goes to show you how sensitive sensors can be.

I do a lot of microsoldering on various products. having schematics available turn a 8 hr job into a 30 minute job, I totally understand your frustration. It should be noted (not that I think it matters), that I am a monkey at understanding circuits. I get the job done though ;D

@LineoftheDead Yeah, schematics would surely be helpful in this instance. The fact that when I opened the switch up the first time and I saw that loose resistor on there which fell off shortly after opening clearly shows how this just has to be the issue. Trying to replace that resistor with a pot set to 100k Ohms and still seeing the console freeze just made me believe that it just wasnt the problem. Now that im thinking about it, considering the unprecise tuneability of the pot and the long wires that run to it might cause interference or might even act as an antenna to pick up signals, thus not making the whole thing work even though it should. If I had a really precise potentiometer or a 100k Ohms resistor in that place again it should work. At least I hope it is a 100k resistor, the usage examples for the M92T36 power supply chip next to the missing resistor show that a 100k resistor is recommended on the place where it is missing now.

Once I find out the package size of these resistors I will be buying some off of mosuer as well (even though the shipping fees are like 10x higher than the actual item im ordering), but it seems to be my only chance here. Perhaps I can measure the size of the resistors next to it and look up a size table online.

On a side note: The online datasheet of the chip states that on pin 2 where the missing resistor is, is not allowing the path to VCCIN to pin 2. I temporarely bridged the spot where the resistor was just to see if it made any difference, which it didnt. In the datasheet is stated that pin 2 is an analog input pin, so it is probably responsable for reading something, perhaps even the battery voltage as VCCIN is essentially the positive battery contact. If the sensor on pin 2 does not work right because the resistor is unprecise, there is a good chance the device cant read the battery voltage correctly and freezes. It also explains why I NEVER see the battery percentage drop or rise while it is running.

Anyways, thanks for the suggestion to give replacing the missing resistor a try again. If it does not work out I will end up trying a reflow method!

Edit: Just found out the specific resistor im looking for is going for 2€ and an additional 20€ of shipping, incredible. But I guess If I cant find the exact resistor somewhere else or on some of my old electronics around the house Ill have to order off of digikey or mouser.

Last edited by ZetShock,

Update:

I was trying to figure out where to get a replacement resistor to put back on the switch from, and surely enough, I found the same resistor and even a very similar power supply chip on the Switch dock board!

Even the layout is quite similar to the power management portion on the switch. Turns out the resistor that goes on pin 2 is a 10k Ohm resistor, not a 100k Ohm. I know this because I measured the loose resistor on the switch before it was lost, and I believe it was around 10k Ohms as well. Also because of another reason. See, without hesitation I went and desoldered the 10k and 100k resistors from the dock board, and then soldered them into place on the switch, first the 10k ohm one and then the 100k ohm one.

The picture is from when I soldered in the 100k resistor. I also made sure they made proper contact and were soldered correctly. And allthough this may not be the best soldering job (there is still flux on), I checked continuity and resistance across two other points that go through the resistor and could confirm that they were soldered in correctly.

Anyways, after soldering in the 10k resistor and booting up the console... It worked for... well about 1 Minute and... freezing again :/

Same with the 100k ohm resistor. I decided to put them back onto the dock board again, as the switch freezes, no matter what or if there is any resistor in that place at all. So it turns out, the issue is not at all related with the missing resistor, sadly.

All evidence points to a lose solder connection on some of the BGA or QFN Chips on the mainboard, as this is the only explanation as to why the device freezes later when turned on the first time of the day and freezes earlier the more I turn the thing on and let it warm up. Also, I am sure the missing resistor is not responsible for reading battery percentage, because the console IS indeed able to read the battery percentage, or at least it updates to a new value every time I boot into the system. The percentage just does not drop or rise quickly enough during the time the console actually runs. I noticed the same with my phone too, the percentage barely updates when I restarted it.

A loose solder connection on any of the chips also explains why I sometimes cant even boot up completeley before it freezes up. Sometimes the Nintendo logo would show up, then a short blackscreen, and thats all, thats when it would sometimes freeze as well.

As a conclusion, all Im left with is reflowing some chips or maybe the whole board. My option to use is either a heat gun, Kapton to cover up plastic connectors and some flux, or, stupidly enough, a regular baking oven. I have the feeling the problem could lie in the Nand flash storage chip which is made by samsung. Like with other devices, when you remove the operating system or critical data while it is running it would just freeze up, because the processor has no data to process anymore. The critical chips that could have a bad solder connectoin are rather large though, so would you guys recommend using the heat gun?

Ill let you guys know when I made further progress in narrowing down the problem.

Additional Update:

So I just left the switch outside in the cold for a little while and then started it up outside while it was still quite cold. It ran for a maximum of one minute, so its really just the fact that thermal expansion makes the difference, not how cool the device is kept while using it, pointing even more to a bad solder connection of the chips. Strangely enough, the fan kicked in, but I could feel the copper pipe that cools the processor was really rather cold. Why would the cpu tell the fan to turn on if the cpu was just about less than room temperature? We currently have 4 degrees C or 40 degrees F right outside here. Perhaps the pin on the processor or wherever the temperature information for the CPU is coming from is not soldered completely? I can just assume...

I was trying to figure out where to get a replacement resistor to put back on the switch from, and surely enough, I found the same resistor and even a very similar power supply chip on the Switch dock board!

Even the layout is quite similar to the power management portion on the switch. Turns out the resistor that goes on pin 2 is a 10k Ohm resistor, not a 100k Ohm. I know this because I measured the loose resistor on the switch before it was lost, and I believe it was around 10k Ohms as well. Also because of another reason. See, without hesitation I went and desoldered the 10k and 100k resistors from the dock board, and then soldered them into place on the switch, first the 10k ohm one and then the 100k ohm one.

The picture is from when I soldered in the 100k resistor. I also made sure they made proper contact and were soldered correctly. And allthough this may not be the best soldering job (there is still flux on), I checked continuity and resistance across two other points that go through the resistor and could confirm that they were soldered in correctly.

Anyways, after soldering in the 10k resistor and booting up the console... It worked for... well about 1 Minute and... freezing again :/

Same with the 100k ohm resistor. I decided to put them back onto the dock board again, as the switch freezes, no matter what or if there is any resistor in that place at all. So it turns out, the issue is not at all related with the missing resistor, sadly.

All evidence points to a lose solder connection on some of the BGA or QFN Chips on the mainboard, as this is the only explanation as to why the device freezes later when turned on the first time of the day and freezes earlier the more I turn the thing on and let it warm up. Also, I am sure the missing resistor is not responsible for reading battery percentage, because the console IS indeed able to read the battery percentage, or at least it updates to a new value every time I boot into the system. The percentage just does not drop or rise quickly enough during the time the console actually runs. I noticed the same with my phone too, the percentage barely updates when I restarted it.

A loose solder connection on any of the chips also explains why I sometimes cant even boot up completeley before it freezes up. Sometimes the Nintendo logo would show up, then a short blackscreen, and thats all, thats when it would sometimes freeze as well.

As a conclusion, all Im left with is reflowing some chips or maybe the whole board. My option to use is either a heat gun, Kapton to cover up plastic connectors and some flux, or, stupidly enough, a regular baking oven. I have the feeling the problem could lie in the Nand flash storage chip which is made by samsung. Like with other devices, when you remove the operating system or critical data while it is running it would just freeze up, because the processor has no data to process anymore. The critical chips that could have a bad solder connectoin are rather large though, so would you guys recommend using the heat gun?

Ill let you guys know when I made further progress in narrowing down the problem.

Additional Update:

So I just left the switch outside in the cold for a little while and then started it up outside while it was still quite cold. It ran for a maximum of one minute, so its really just the fact that thermal expansion makes the difference, not how cool the device is kept while using it, pointing even more to a bad solder connection of the chips. Strangely enough, the fan kicked in, but I could feel the copper pipe that cools the processor was really rather cold. Why would the cpu tell the fan to turn on if the cpu was just about less than room temperature? We currently have 4 degrees C or 40 degrees F right outside here. Perhaps the pin on the processor or wherever the temperature information for the CPU is coming from is not soldered completely? I can just assume...

Last edited by ZetShock,

First thing to do is to heat up the whole PCB in a toaster oven to around 180 or 190 celcius, then carefully take it out and hit the BGA chips with the heatgun while still making sure to heat the rest of the PCB as well. If you do not then the board with warp and fuck things up 100x more. I am willing to bet it is the main CPU that is having the problem, certainly not the flash memory. If it was the flash memory then the unit likely would not completely freeze up, you would just be stuck at the same screen while noticing some activity because the OS would be saying "Give me data. I am waiting for data!" and the flash memory would just go "durrrr", but you would likely still get sound and some user control or ongoing visual output.

Ram could possibly do this as well, but that it not going to heat up as quickly as the CPU. Like I said, my bet is the CPU. Certainly doesn't hurt to make sure that you reflow all bga chips. The only real way to determine if the solder balls have fully reflowed is to slightly tap against the chip to see if it freely moves. But you have to do it ever so slightly to not fuck everything up. You don't want to make it any hotter than necessary.

Ideally, the right setup is a reflow oven, or an IR preheater and a hot air station. The downside to using a heatgun it that you might blow resistors and other small components all over the place.

I have done MANY reflows in my time on all types of electronics. The only thing I have ever failed with was those damn xbox 360's. Everything else I was able to repair. The 360's likely failed to be repaired because idiots were trying the towel trick and other stupid shit on them before bringing them to me.

Ram could possibly do this as well, but that it not going to heat up as quickly as the CPU. Like I said, my bet is the CPU. Certainly doesn't hurt to make sure that you reflow all bga chips. The only real way to determine if the solder balls have fully reflowed is to slightly tap against the chip to see if it freely moves. But you have to do it ever so slightly to not fuck everything up. You don't want to make it any hotter than necessary.

Ideally, the right setup is a reflow oven, or an IR preheater and a hot air station. The downside to using a heatgun it that you might blow resistors and other small components all over the place.

I have done MANY reflows in my time on all types of electronics. The only thing I have ever failed with was those damn xbox 360's. Everything else I was able to repair. The 360's likely failed to be repaired because idiots were trying the towel trick and other stupid shit on them before bringing them to me.

First thing to do is to heat up the whole PCB in a toaster oven to around 180 or 190 celcius, then carefully take it out and hit the BGA chips with the heatgun while still making sure to heat the rest of the PCB as well. If you do not then the board with warp and fuck things up 100x more. I am willing to bet it is the main CPU that is having the problem, certainly not the flash memory. If it was the flash memory then the unit likely would not completely freeze up, you would just be stuck at the same screen while noticing some activity because the OS would be saying "Give me data. I am waiting for data!" and the flash memory would just go "durrrr", but you would likely still get sound and some user control or ongoing visual output.

Ram could possibly do this as well, but that it not going to heat up as quickly as the CPU. Like I said, my bet is the CPU. Certainly doesn't hurt to make sure that you reflow all bga chips. The only real way to determine if the solder balls have fully reflowed is to slightly tap against the chip to see if it freely moves. But you have to do it ever so slightly to not fuck everything up. You don't want to make it any hotter than necessary.

Ideally, the right setup is a reflow oven, or an IR preheater and a hot air station. The downside to using a heatgun it that you might blow resistors and other small components all over the place.

I have done MANY reflows in my time on all types of electronics. The only thing I have ever failed with was those damn xbox 360's. Everything else I was able to repair. The 360's likely failed to be repaired because idiots were trying the towel trick and other stupid shit on them before bringing them to me.

So finally, after many days of troubleshooting, this thread can finally come to an end, we have good news! The Switch is finally running functionally, I didnt even get one single freeze since the console has been running for a few hours now!

You see, I tried improvisingly reflowing the mainboard in my cooking oven, which, to be fair might not be the most precise in temperature, but it did the trick. I was following a tutorial on Youtube about reflowing in a regular oven set to 200C or 392F for about 8 Minutes while the mainboard is suspended on rolled up aluminum foil balls. Surely enough, I actually gave up on the idea and cancelled it after about 3 Minutes of reflowing, thinking it would just destroy something. After reinstalling the mainboard the thing just works flawlessly to my surprise. What I really did not expect is the short amout of heat to actually have helped in the end.

So, what can we conclude? It was certainly not the missing resistor, in fact, I have yet to find any function that is not working right because of that missing resistor on pin 2 of the M92T36 chip. The previous owner most probably left the device out in the cold and brought it back inside to warm up very often, or the chip was just not soldered on correctly during manufacturing. The little troublemaker was, as @DeadlyFoez suggested, probably the CPU or if not then the DRAM.

Also, since its not freezing up all the time, the docking function, as well as charging works now as well, and I can even finally see the battery percentage rise or fall live!

Now, of course the oven method, or at least the way I have done it, is not a permanent fix, and in fact, that loose solder joint on one of the chips is going to lose contact sooner or later anyways. But by the time that happens I will either reflow the board the right way or find a professional to do it for me. I might know a little shop nearby that does BGA reflowing as well, we'll see. Anyways, if anyone does ever run into this issue, and people surely will because I can't be the owner of the only switch that has a bad solder connection on the whole world, this thread may serve as a good help to find a solution, like it did for me as well.

I'd like to thank everyone for suggesting how to fix the issue, and for taking their time to help me troubleshoot. I wish I would have tried reflowing earlier, but at least we came to a solution in the end.

I might stick around this forum for longer though, some threads about the switch are rather interesting and people actually contribute to threads.

So, if no further questoins come up, we might consider this thread as closed. Thanks!

Thats great news. I like being right.

Chances are, a reflow did not occur, and you will likely end up with this issue again in just a short period of time. What likely did happen, much like with everyone doing the towel trick on the 360's, is that it heated up enough to flex the board and break off some of the corrosion on the contact. You still will likely have to do a proper reflow to it at a later point in time... but at least now you know for sure what the underlying problem is.

Never trust the temps of an oven. They have hot spots and cold spots and do not accurately monitor the temps. Using a convection oven is a little better, but still a bad way of doing it. You got lucky.

Also, keep in mind that these components are only supposed to get reflowed a certain number of times, and with each time you heat the components and PCB up to or close to reflow temps it will do slight amounts of damage. Delaminating PCB's are usually the first things to happen. Additionally, before reflowing any PCB, it is best to "bake" the board to remove any moisture from the board. That process is usually an hour or longer. If there is any moisture in the PCB when going to do a reflow then the PCB will delaminate and create bubbles between the layers and totally ruin the PCB.

--------------------- MERGED ---------------------------

Last thing. Before you cook any food in your oven, run it on a "self clean" cycle. You dont want any of that shit that got airborne to end up in your food and poison you.

Chances are, a reflow did not occur, and you will likely end up with this issue again in just a short period of time. What likely did happen, much like with everyone doing the towel trick on the 360's, is that it heated up enough to flex the board and break off some of the corrosion on the contact. You still will likely have to do a proper reflow to it at a later point in time... but at least now you know for sure what the underlying problem is.

Never trust the temps of an oven. They have hot spots and cold spots and do not accurately monitor the temps. Using a convection oven is a little better, but still a bad way of doing it. You got lucky.

Also, keep in mind that these components are only supposed to get reflowed a certain number of times, and with each time you heat the components and PCB up to or close to reflow temps it will do slight amounts of damage. Delaminating PCB's are usually the first things to happen. Additionally, before reflowing any PCB, it is best to "bake" the board to remove any moisture from the board. That process is usually an hour or longer. If there is any moisture in the PCB when going to do a reflow then the PCB will delaminate and create bubbles between the layers and totally ruin the PCB.

--------------------- MERGED ---------------------------

Last thing. Before you cook any food in your oven, run it on a "self clean" cycle. You dont want any of that shit that got airborne to end up in your food and poison you.

the oven method is shit (no offense, but theres no sense in cooking parts that dont need to be cooked) - heres my exact methods on reflowing,

https://www.amazon.com/DEWALT-D26960K-Heavy-Duty-Display/dp/B007X2ATZE/ref=sr_1_3?ie=UTF8&qid=1513481909&sr=8-3&keywords=dewalt+heat+gun

I lay the circuit board on a flat wooden table located in my garage w/ low heat set to 750F, turn on low heat and point the gun at the circuit board about 12 inches above (preheat) and watch the LCD display... when the gun hits 750F I sway the gun back and forth while getting closer to the circuit board (~1" p 10 seconds), center the gun over desired IC 2" above and hold for 30 seconds, then repeat for next IC. I hit all fets and BGAs. when happy, reverse the "getting closer" procedure. turn gun off and walk away for 10 minutes. come back, hover hand over board to see if its still hot. waiting longer/until its cold is totally fine - but when your ready for reassembly pay attention to any thermal conductors (flip marshmallow pads/clean with IPA, add AS5 to them if split)

Only reflow CPU/Northbridge/Southbridge if it is NEEDED, save them for last and do them one by one, reflowing these is complete bullshit - you are NOT reflowing them (anyone that says otherwise is full of shit), you are heating up the internals and getting a temporary fix via thermal expansion.

--------------------- MERGED ---------------------------

--------------------- MERGED ---------------------------

https://www.amazon.com/DEWALT-D26960K-Heavy-Duty-Display/dp/B007X2ATZE/ref=sr_1_3?ie=UTF8&qid=1513481909&sr=8-3&keywords=dewalt+heat+gun

I lay the circuit board on a flat wooden table located in my garage w/ low heat set to 750F, turn on low heat and point the gun at the circuit board about 12 inches above (preheat) and watch the LCD display... when the gun hits 750F I sway the gun back and forth while getting closer to the circuit board (~1" p 10 seconds), center the gun over desired IC 2" above and hold for 30 seconds, then repeat for next IC. I hit all fets and BGAs. when happy, reverse the "getting closer" procedure. turn gun off and walk away for 10 minutes. come back, hover hand over board to see if its still hot. waiting longer/until its cold is totally fine - but when your ready for reassembly pay attention to any thermal conductors (flip marshmallow pads/clean with IPA, add AS5 to them if split)

Only reflow CPU/Northbridge/Southbridge if it is NEEDED, save them for last and do them one by one, reflowing these is complete bullshit - you are NOT reflowing them (anyone that says otherwise is full of shit), you are heating up the internals and getting a temporary fix via thermal expansion.

--------------------- MERGED ---------------------------

my favorite is when moisture vaporizes and causes a flip chip to clap the PCB - spreadings its balls everywhere xDThats great news. I like being right.

Chances are, a reflow did not occur, and you will likely end up with this issue again in just a short period of time. What likely did happen, much like with everyone doing the towel trick on the 360's, is that it heated up enough to flex the board and break off some of the corrosion on the contact. You still will likely have to do a proper reflow to it at a later point in time... but at least now you know for sure what the underlying problem is.

Never trust the temps of an oven. They have hot spots and cold spots and do not accurately monitor the temps. Using a convection oven is a little better, but still a bad way of doing it. You got lucky.

Also, keep in mind that these components are only supposed to get reflowed a certain number of times, and with each time you heat the components and PCB up to or close to reflow temps it will do slight amounts of damage. Delaminating PCB's are usually the first things to happen. Additionally, before reflowing any PCB, it is best to "bake" the board to remove any moisture from the board. That process is usually an hour or longer. If there is any moisture in the PCB when going to do a reflow then the PCB will delaminate and create bubbles between the layers and totally ruin the PCB.

--------------------- MERGED ---------------------------

Last thing. Before you cook any food in your oven, run it on a "self clean" cycle. You dont want any of that shit that got airborne to end up in your food and poison you.

--------------------- MERGED ---------------------------

all guns are different btw - I forgot to mention thatthe oven method is shit (no offense, but theres no sense in cooking parts that dont need to be cooked) - heres my exact methods on reflowing,

https://www.amazon.com/DEWALT-D2696...id=1513481909&sr=8-3&keywords=dewalt+heat+gun

https://www.amazon.com/DEWALT-D2696...id=1513481909&sr=8-3&keywords=dewalt+heat+gun

https://www.amazon.com/DEWALT-D2696...id=1513481909&sr=8-3&keywords=dewalt+heat+gun

I lay the circuit board on a flat wooden table located in my garage w/ low heat set to 750F, turn on low heat and point the gun at the circuit board about 12 inches above (preheat) and watch the LCD display... when the gun hits 750F I sway the gun back and forth while getting closer to the circuit board (~1" p 10 seconds), center the gun over desired IC 2" above and hold for 30 seconds, then repeat for next IC. I hit all fets and BGAs. when happy, reverse the "getting closer" procedure. turn gun off and walk away for 10 minutes. come back, hover hand over board to see if its still hot. waiting longer/until its cold is totally fine - but when your ready for reassembly pay attention to any thermal conductors (flip marshmallow pads/clean with IPA, add AS5 to them if split)

Only reflow CPU/Northbridge/Southbridge if it is NEEDED, save them for last and do them one by one, reflowing these is complete bullshit - you are NOT reflowing them (anyone that says otherwise is full of shit), you are heating up the internals and getting a temporary fix via thermal expansion.

--------------------- MERGED ---------------------------

my favorite is when moisture vaporizes and causes a flip chip to clap the PCB - spreadings its balls everywhere xD

Thats great news. I like being right.

Chances are, a reflow did not occur, and you will likely end up with this issue again in just a short period of time. What likely did happen, much like with everyone doing the towel trick on the 360's, is that it heated up enough to flex the board and break off some of the corrosion on the contact. You still will likely have to do a proper reflow to it at a later point in time... but at least now you know for sure what the underlying problem is.

Never trust the temps of an oven. They have hot spots and cold spots and do not accurately monitor the temps. Using a convection oven is a little better, but still a bad way of doing it. You got lucky.

Also, keep in mind that these components are only supposed to get reflowed a certain number of times, and with each time you heat the components and PCB up to or close to reflow temps it will do slight amounts of damage. Delaminating PCB's are usually the first things to happen. Additionally, before reflowing any PCB, it is best to "bake" the board to remove any moisture from the board. That process is usually an hour or longer. If there is any moisture in the PCB when going to do a reflow then the PCB will delaminate and create bubbles between the layers and totally ruin the PCB.

--------------------- MERGED ---------------------------

Last thing. Before you cook any food in your oven, run it on a "self clean" cycle. You dont want any of that shit that got airborne to end up in your food and poison you.

Ill make sure to do a self clean cycle on my heat gun. But yeah, the console is still working fine, but as you mentioned it will probably have the same issue sooner or later, probably when I least need it. I will try to find something more accurate for reflowing or I will try @LineoftheDead 's method.

the oven method is shit (no offense, but theres no sense in cooking parts that dont need to be cooked) - heres my exact methods on reflowing,

https://www.amazon.com/DEWALT-D2696...id=1513481909&sr=8-3&keywords=dewalt+heat+gun

https://www.amazon.com/DEWALT-D2696...id=1513481909&sr=8-3&keywords=dewalt+heat+gun

https://www.amazon.com/DEWALT-D2696...id=1513481909&sr=8-3&keywords=dewalt+heat+gun

I lay the circuit board on a flat wooden table located in my garage w/ low heat set to 750F, turn on low heat and point the gun at the circuit board about 12 inches above (preheat) and watch the LCD display... when the gun hits 750F I sway the gun back and forth while getting closer to the circuit board (~1" p 10 seconds), center the gun over desired IC 2" above and hold for 30 seconds, then repeat for next IC. I hit all fets and BGAs. when happy, reverse the "getting closer" procedure. turn gun off and walk away for 10 minutes. come back, hover hand over board to see if its still hot. waiting longer/until its cold is totally fine - but when your ready for reassembly pay attention to any thermal conductors (flip marshmallow pads/clean with IPA, add AS5 to them if split)

Only reflow CPU/Northbridge/Southbridge if it is NEEDED, save them for last and do them one by one, reflowing these is complete bullshit - you are NOT reflowing them (anyone that says otherwise is full of shit), you are heating up the internals and getting a temporary fix via thermal expansion.

--------------------- MERGED ---------------------------

my favorite is when moisture vaporizes and causes a flip chip to clap the PCB - spreadings its balls everywhere xD

--------------------- MERGED ---------------------------

all guns are different btw - I forgot to mention that

Thanks for the detailed way of doing this. I have recently bought myself a hot air station for smd work, and it does go up to 750F. I can also set the airflow if needed. Also I could put Kapton tape over any components that are not causing the problem anyways as well as any plastic connectors. Your method works for smaller components and medium sized BGA chips, but yeah, as you mentioned reflowing the whole CPU (which was probably causing the problem) does most likely not work with this method. Ill just wait and see when the console starts acting up again, but when the time comes I will see if I can find anyone to reflow the chip for me using one of these fancy IR stations with cameras and what not as that would be my only chance of actually fixing it.

This is my favorite thread ever and most useful one I've seen in a long time. Glad you got your problem solved! Excuse the mannerism of other users as they can be very blunt with knowledge.

This is my favorite thread ever and most useful one I've seen in a long time. Glad you got your problem solved! Excuse the mannerism of other users as they can be very blunt with knowledge.

Thanks for the feedback! I was hoping to get my problem out to the web so people with the same issue would be able to troubleshoot better using this thread. I currently still need to find someone to reflow the CPU/GPU chip for me as I know it will definitely end up not working again in a few weeks or months. I've read the oven and heat gun methods do not work well, so unless I can find myself an Infrared BGA station soon (which I wont), I will need to keep looking for a repair shop that does this for a reasonable price.

Nooooo. I never said anything about overheating. It obviously is not overheating. Take a class on thermal dynamics and then come back to us. You obviously do not understand how heat makes materials expand and even a few degrees can separate weak joints.

You cover all plastic parts with foil or kapton tape. It is simple to do. Even a heat gun can reflow if you are careful enough.

it's THERMODYNAMICS, not THERMAL DYNAMICS. Take a class in spelling and then come back to us.

Also, I think material sciences would better explain what happens to things physically when heat is applied.

(offtopic but still)

Glad to see you saved yourself some money.

Last edited by Taffy,

If thats the only thing you can pick out that I have said wrong with the wealth of knowledge and help that I have provided here then I am doing pretty good considering I had beer in me and had just smoked some of my most recent harvest.it's THERMODYNAMICS, not THERMAL DYNAMICS. Take a class in spelling and then come back to us.

Glad you are providing so much to the conversation. I will be sure to watch out for any spelling mistakes that you make and give you a hard time about it later, Mr. Perfect.

Similar threads

- Replies

- 0

- Views

- 203

- Replies

- 2

- Views

- 614

- Replies

- 0

- Views

- 525

- Replies

- 0

- Views

- 193

- Replies

- 0

- Views

- 139

Site & Scene News

New Hot Discussed

-

-

58K views

Nintendo Switch firmware 18.0.0 has been released

It's the first Nintendo Switch firmware update of 2024. Made available as of today is system software version 18.0.0, marking a new milestone. According to the patch... -

29K views

GitLab has taken down the Suyu Nintendo Switch emulator

Emulator takedowns continue. Not long after its first release, Suyu emulator has been removed from GitLab via a DMCA takedown. Suyu was a Nintendo Switch emulator... -

21K views

Atmosphere CFW for Switch updated to pre-release version 1.7.0, adds support for firmware 18.0.0

After a couple days of Nintendo releasing their 18.0.0 firmware update, @SciresM releases a brand new update to his Atmosphere NX custom firmware for the Nintendo...by ShadowOne333 94 -

18K views

Wii U and 3DS online services shutting down today, but Pretendo is here to save the day

Today, April 8th, 2024, at 4PM PT, marks the day in which Nintendo permanently ends support for both the 3DS and the Wii U online services, which include co-op play...by ShadowOne333 176 -

15K views

GBAtemp Exclusive Introducing tempBOT AI - your new virtual GBAtemp companion and aide (April Fools)

Hello, GBAtemp members! After a prolonged absence, I am delighted to announce my return and upgraded form to you today... Introducing tempBOT AI 🤖 As the embodiment... -

12K views

Pokemon fangame hosting website "Relic Castle" taken down by The Pokemon Company

Yet another casualty goes down in the never-ending battle of copyright enforcement, and this time, it hit a big website which was the host for many fangames based and...by ShadowOne333 65 -

11K views

MisterFPGA has been updated to include an official release for its Nintendo 64 core

The highly popular and accurate FPGA hardware, MisterFGPA, has received today a brand new update with a long-awaited feature, or rather, a new core for hardcore...by ShadowOne333 51 -

11K views

Apple is being sued for antitrust violations by the Department of Justice of the US

The 2nd biggest technology company in the world, Apple, is being sued by none other than the Department of Justice of the United States, filed for antitrust...by ShadowOne333 80 -

10K views

The first retro emulator hits Apple's App Store, but you should probably avoid it

With Apple having recently updated their guidelines for the App Store, iOS users have been left to speculate on specific wording and whether retro emulators as we... -

9K views

"TMNT: The Hyperstone Heist" for the SEGA Genesis / Mega Drive gets a brand new DX romhack with new features

The romhacking community is always a source for new ways to play retro games, from completely new levels or stages, characters, quality of life improvements, to flat...by ShadowOne333 36

-

-

-

223 replies

Nintendo Switch firmware 18.0.0 has been released

It's the first Nintendo Switch firmware update of 2024. Made available as of today is system software version 18.0.0, marking a new milestone. According to the patch...by Chary -

176 replies

Wii U and 3DS online services shutting down today, but Pretendo is here to save the day

Today, April 8th, 2024, at 4PM PT, marks the day in which Nintendo permanently ends support for both the 3DS and the Wii U online services, which include co-op play...by ShadowOne333 -

169 replies

GBAtemp Exclusive Introducing tempBOT AI - your new virtual GBAtemp companion and aide (April Fools)

Hello, GBAtemp members! After a prolonged absence, I am delighted to announce my return and upgraded form to you today... Introducing tempBOT AI 🤖 As the embodiment...by tempBOT -

146 replies

GitLab has taken down the Suyu Nintendo Switch emulator

Emulator takedowns continue. Not long after its first release, Suyu emulator has been removed from GitLab via a DMCA takedown. Suyu was a Nintendo Switch emulator...by Chary -

96 replies

The first retro emulator hits Apple's App Store, but you should probably avoid it

With Apple having recently updated their guidelines for the App Store, iOS users have been left to speculate on specific wording and whether retro emulators as we...by Scarlet -

94 replies

Atmosphere CFW for Switch updated to pre-release version 1.7.0, adds support for firmware 18.0.0

After a couple days of Nintendo releasing their 18.0.0 firmware update, @SciresM releases a brand new update to his Atmosphere NX custom firmware for the Nintendo...by ShadowOne333 -

80 replies

Apple is being sued for antitrust violations by the Department of Justice of the US

The 2nd biggest technology company in the world, Apple, is being sued by none other than the Department of Justice of the United States, filed for antitrust...by ShadowOne333 -

74 replies

Delta emulator now available on the App Store for iOS

The time has finally come, and after many, many years (if not decades) of Apple users having to side load emulator apps into their iOS devices through unofficial...by ShadowOne333 -

65 replies

Pokemon fangame hosting website "Relic Castle" taken down by The Pokemon Company

Yet another casualty goes down in the never-ending battle of copyright enforcement, and this time, it hit a big website which was the host for many fangames based and...by ShadowOne333 -

53 replies

Nintendo "Indie World" stream announced for April 17th, 2024

Nintendo has recently announced through their social media accounts that a new Indie World stream will be airing tomorrow, scheduled for April 17th, 2024 at 7 a.m. PT...by ShadowOne333

-

Popular threads in this forum

General chit-chat

- No one is chatting at the moment.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

@

RedColoredStars:

There is an actual trailer with footage too. lol. Going to watch it tonight. Grabbed it from... a place.

@

RedColoredStars:

There is an actual trailer with footage too. lol. Going to watch it tonight. Grabbed it from... a place. -

-

@

SylverReZ:

@Psionic Roshambo, JonTron's back yet again until he disappears into the void for another 6 or so months.+1

@

SylverReZ:

@Psionic Roshambo, JonTron's back yet again until he disappears into the void for another 6 or so months.+1 -

-