I realize the thread title is a bit odd, and is not very clear.

If you think of a better title after reading my question, feel free to suggest.

Alright, so I have recently made breakthroughs in my BD design, but my biggest issue now is that the bicycle reflector - made of plastic - breaks easily and constantly. BDv4.3 is near perfect- the only flaw is the breaking of the reflector piece.

This is the exact piece I am referring to

(Click to enlarge)

(Click to enlarge)

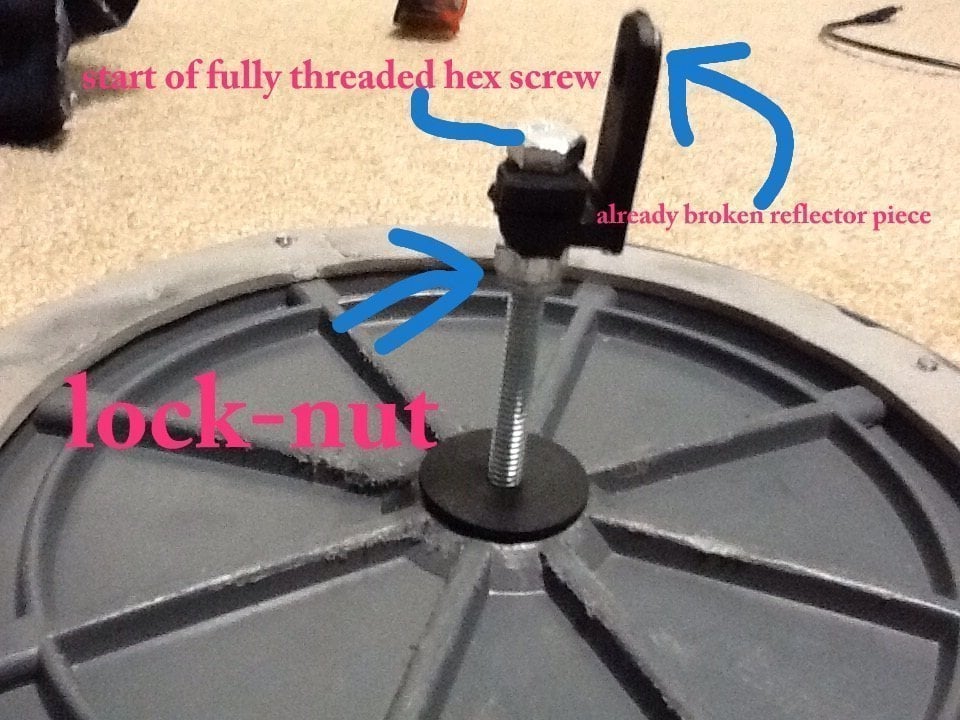

What I have been doing is removing the lens/reflector piece, removing the screw, drilling the screw hole with a 1/4 drill bit, and then using 4" full thread hex screw, I replace the screw and lock the reflectorpiece onto my bicycle with a lock nut.

Here is a picture of v4.3 to help perspective- off the bicycle.

**note the plasic piece I need is not in this picture, it already broke off.

(Click to enlarge)

(Click to enlarge)

Now to get to the point,

I need this piece specifically and I need it to be made of a very strong material- I am looking for suggestions on what material I should make it out of. If necessary, I will produce it myself via Sand-casting, if other methods are needed that's fine too. Is steel out of the question?

Budget is not a concern.

To be clear again:

I do not need the red X'd piece, but I do need the screw-in area on the clamp

If you think of a better title after reading my question, feel free to suggest.

Alright, so I have recently made breakthroughs in my BD design, but my biggest issue now is that the bicycle reflector - made of plastic - breaks easily and constantly. BDv4.3 is near perfect- the only flaw is the breaking of the reflector piece.

This is the exact piece I am referring to

(Click to enlarge)

(Click to enlarge)What I have been doing is removing the lens/reflector piece, removing the screw, drilling the screw hole with a 1/4 drill bit, and then using 4" full thread hex screw, I replace the screw and lock the reflectorpiece onto my bicycle with a lock nut.

Here is a picture of v4.3 to help perspective- off the bicycle.

**note the plasic piece I need is not in this picture, it already broke off.

(Click to enlarge)

(Click to enlarge)Now to get to the point,

I need this piece specifically and I need it to be made of a very strong material- I am looking for suggestions on what material I should make it out of. If necessary, I will produce it myself via Sand-casting, if other methods are needed that's fine too. Is steel out of the question?

Budget is not a concern.

To be clear again:

I do not need the red X'd piece, but I do need the screw-in area on the clamp

Last edited by jonthedit,